Having returned from Hannover Fair where everything was Industrie 4.0, it’s time to revisit what Industrie 4.0 is and where the Internet of Things, the Industrial Internet of Things, and PROFINET fit. In words: PROFINET provides data in the Industrial Internet of Things which is a shared subset of Industrie 4.0 and the Internet of Things. Easier seen than read:

Industrie 4.0 is a very comprehensive, very high-level overview of production systems from supplier to finished goods. A description from the ZVEI website:

“Industrie 4.0” stands for the complete digitisation and integration of the industrial value chain. The combining of information and communication technology with automation technology to form the Internet of things and services allows increasingly higher degrees of networking in and between production facilities, from the suppliers to the customers. This goes hand in hand with the digitisation of the product and service offering, which makes new business models possible. Ultimately, Industrie 4.0 is the realisation of the smart factory in the digital value network.

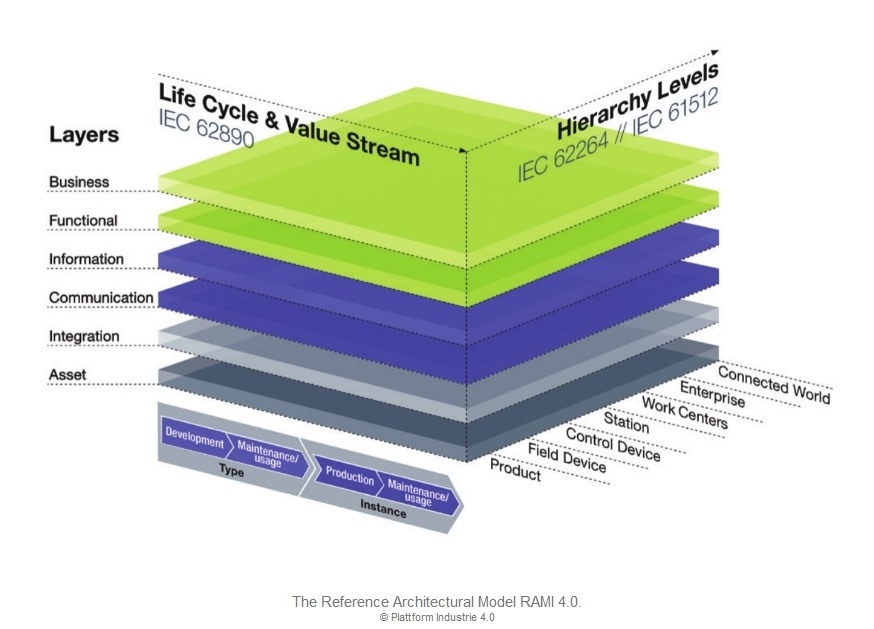

The Reference Architectural Model 4.0 (RAMI 4.0) visualizes this:

The role of PROFINET is at the lower levels of this architecture model.

At Hannover Fair almost every booth referenced Industrie 4.0 (including ours – “PROFINET – The Backbone of Industrie 4.0”) and many referenced OPC UA as the way to move data to the cloud. PI, SAP, Microsoft, IBM, and others demonstrated this in their booths. PI has partnered with OPC because we believe that it is a proven, open-standard method of moving information up from the controller to the cloud. There are other methods and other protocols, but OPC UA makes sense to us. Like PROFINET, it was born and raised in the industrial space. See the PROFIblog post on the four paths from sensor to cloud for more on the topic.

The PROFINET of Things provides the data for IIoT which is a subset of IIoT and Industrie 4.0. The PROFINET of Things provides Data Access, Uptime, and Openness.

–Carl Henning