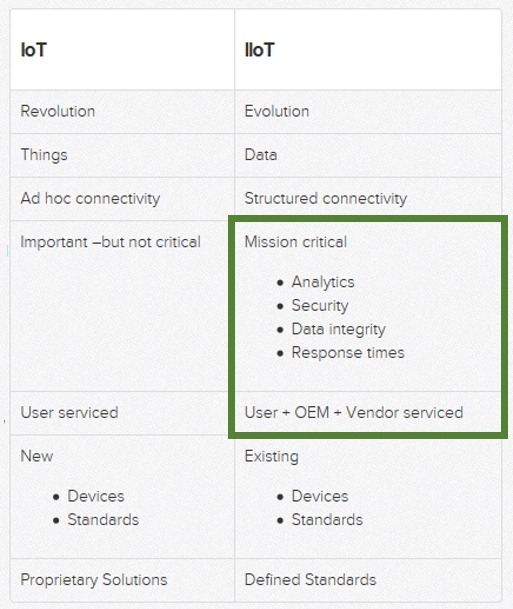

Continuing our examination of PROFINET as THE provider of data to the Industrial Internet of Things, we look at additional features of PROFINET – compared to characteristics needed in the IIoT.

Uptime is the answer to the mission critical and professional services characteristics of IIoT.

Diagnostics

Diagnostics provide a means of preventing downtime and recovering from downtime quickly. PROFINET builds on the concepts of PROFIBUS by providing diagnosis of problems at the device, module, and channel levels. For example, if a device goes offline, a module is missing, or a channel misbehaves (like a broken wire), alarms are sounded. Because PROFINET mandates the use of standard IT protocols like LLDP and SNMP, network problems can be highlighted before a shutdown. (See PROFINET and IT Protocols for details.)

Simple Device Replacement is a fringe benefit of requiring LLDP. Replace a failed device without using a computer or doing any kind of configuration. That shortens downtime! Here’s the how and the why:

Fault Tolerance

One sure way to make certain the automation system keeps running is to have redundant network media (and redundant networks), redundant controllers (aka “hot standby”), and redundant devices. PROFINET also supports redundant wireless access points. By the way, PROFINET is the only Industrial Ethernet that has this level of redundancy. Take a minute (literally) to learn about PROFINET redundancy.

Security

Users should think about security as downtime prevention. Sadly, the tendency is it ignore the problem. Manufacturing is the most targeted industry by hackers – not retail, not finance, manufacturing! It is imperative that users educate themselves and act to prevent being hacked. There are many resources, but start with the PROFINET Security Guideline.

PROFINET of Things: Uptime is a differentiator for PROFINET and a requirement of the Industrial Internet of Things. Next up – PROFINET of Things: Openness.

–Carl Henning