The Easy Way to PROFINET:

Developing & Certifying a PROFINET Product

Introduction

PROFINET is the open, cross-vendor Industrial Ethernet standard for discrete and process automation. There are many choices of ways to add PROFINET to an automation device that it can seem daunting to know where to start. The starting point depends on the type of product, its existing design, quantity expected, and time to market needed. This page focuses on the on the development and integration of PROFINET products and their certification. It covers four main sections that guide device manufacturers through the process of making their own PROFINET device:

Additional Resource: PROFINET Community Forum

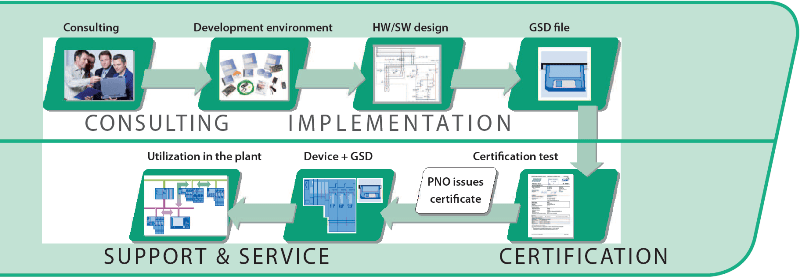

Product development cycle

Every device development project undergoes a product development cycle. An example of this process for PROFINET is presented here. It includes four main stages.

Integration of an industrial communication interface into an automation device begins with information gathering to determine the functionality of your industrial networks along with familiarization about the task at hand. PI itself, as well as a number of its member companies can provide you with comprehensive information here. Advice is available from various PI Competence Centers, solution providers, books, brochures, seminars, and Developer Workshops for getting to know PROFINET.

Individual consulting services support you, as a manufacturer, in every phase of implementation. Here are some typical questions:

Development proceeds faster to our goal if we don’t have to reinvent the wheel. In order to bring PROFINET into automation devices quickly and efficiently, the expertise of PI members on the following topics is available:

Development environment: A variety of starter kits and evaluation boards are available for almost every implementation method. These complete sets enable a quick introduction to development activities and often contain a complete development environment.

Implementation options: Depending on the functionality required (Conformance Class), it is essential to select the suitable type of implementation for each individual case. The available development capacity, company expertise, expected costs to produce the interface, and the time to market also play a large role.

Hardware/software design: The plan of action and expenditure required for hardware and software design depend heavily on the selected implementation method. Here, you can carry out the development work independently or work collaboratively with a development partner.

Device description file: To enable fast and easy configuration of an automation system, manufacturers of field devices must provide a PROFINET device description file. This so-called "General Station Description file" (GSD file) contains all the information needed to configure a device. The GSD files for PROFINET are XML-based and enable multiple product variants and different languages to be captured in one file.

Once your device is certified, it is now ready for the market. Make sure your package is complete, including sales literature and web presence. Also, make sure your sales force thoroughly understands the product. GSD files should be included in your package, or preferably made available over the Internet.

You may have your own routes to market, but PI can help you with:

- A member-maintained on-line product database at www.profibus.com

- Electronic newsletters such as PROFINEWS with large distribution lists which can be used to promote your product and generate sales leads

These services are free to members. Your local Regional PI Association office (that’s us in North America) will also be able to help by offering the chance to advertise and to exhibit at regional events. The advertising and exhibiting opportunities in North America are detailed here. Most of these are excellent ways to meet new customers and to network with like-minded PROFINET people.

PROFINET communication in industrial plants is based on IEC 61158 and IEC 61784. In addition, IEC 62061/ ISO 13849-1 apply to safety modules and devices. To ensure interoperability and conformity of automation devices from different manufacturers, device certification by an accredited PI Test Laboratory (PITL) is mandatory for PROFINET. Even though every PROFINET device must be certified, the effort required for successful certification varies depending on the technology used.

For you, the manufacturer, certification is as easy as can be: The fully developed PROFINET device is tested by an accredited test laboratory. After successful testing you, the manufacturer, can apply for a certificate from the PI, using the test report as a basis.

Implementation options

Device manufacturers wanting to equip an automation device with a PROFINET interface have different options for implementation. Before deciding on a specific implementation method, it’s important to first determine which functions are to be supported by the PROFINET automation device.

Real-Time Requirements

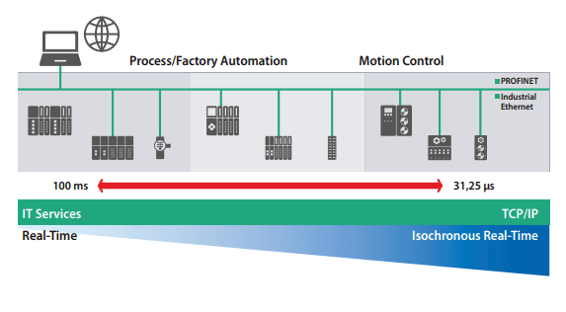

IEEE 802.3 ensures problem-free communication between PROFINET automation devices and among PROFINET automation devices and other standard Ethernet devices. For applications with very stringent real-time requirements, PROFINET offers mechanisms that enable both standard and real-time communication to take place in parallel. Communication with PROFINET can, therefore, be scaled using three different performance levels, which build on each other:

Conformance Classes

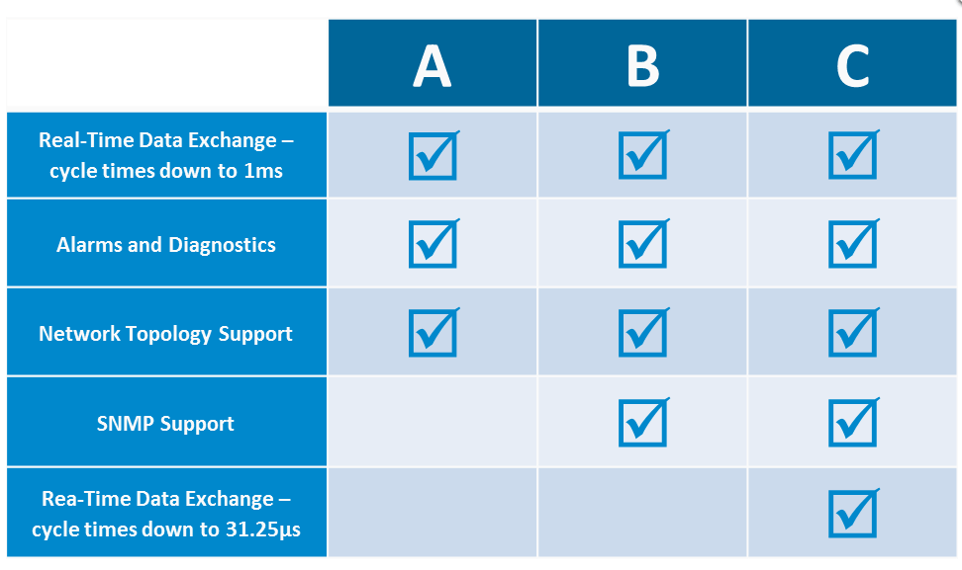

To meet the different requirements of automation systems, three Conformance Classes that build upon one another are defined for PROFINET. Each class has a functional scope determined for the typical area of application.

CC-A: CC-A includes the use of existing Ethernet network infrastructure, including integration of basic PROFINET functions. All IT services can be used without restriction. Examples of typical applications are found in building automation and process automation.

CC-B: The functional scope of CC-B comprises the functions of CC-A plus support for user-friendly device replacement without the need for an engineering tool. Furthermore, Simple Network Management Protocol (SNMP) supports extended device diagnostics of network functions, such as port status messages.

CC-C: The functional scope of CC-C comprises all the functions of CC-B plus it supports high-precision and deterministic data transmission, including isochronous applications. The integrated optional media redundancy enables smooth switchover of I/O data traffic if a fault occurs.

Implementation Options

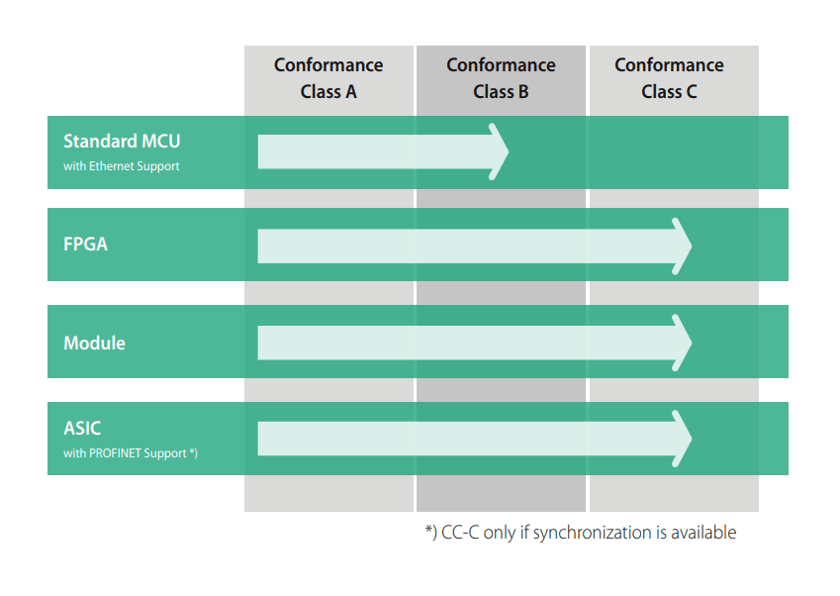

Depending on the Conformance Class required, different types of implementation are available for each individual case.

In principle, the following options are available:

- Standard microcontroller unit (MCU) with integrated or external standard Ethernet controller or FPGA

- FPGA with internal or external standard or IRT-capable switch

- Module with standard microcontroller or with microcontroller with IRT hardware support

- ASIC with IRT hardware support and IRT-capable switch

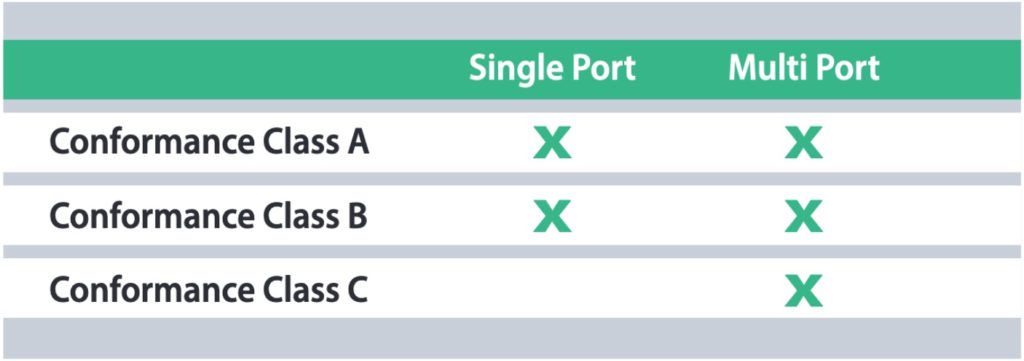

CC-A and CC-B provide the possibility of implementing a single-port interface. However, the economic viability of the solution should be taken into consideration. Including a two-port interface (integrated switch) can be beneficial for customers seeking to implement a line topology in their network.

development paths

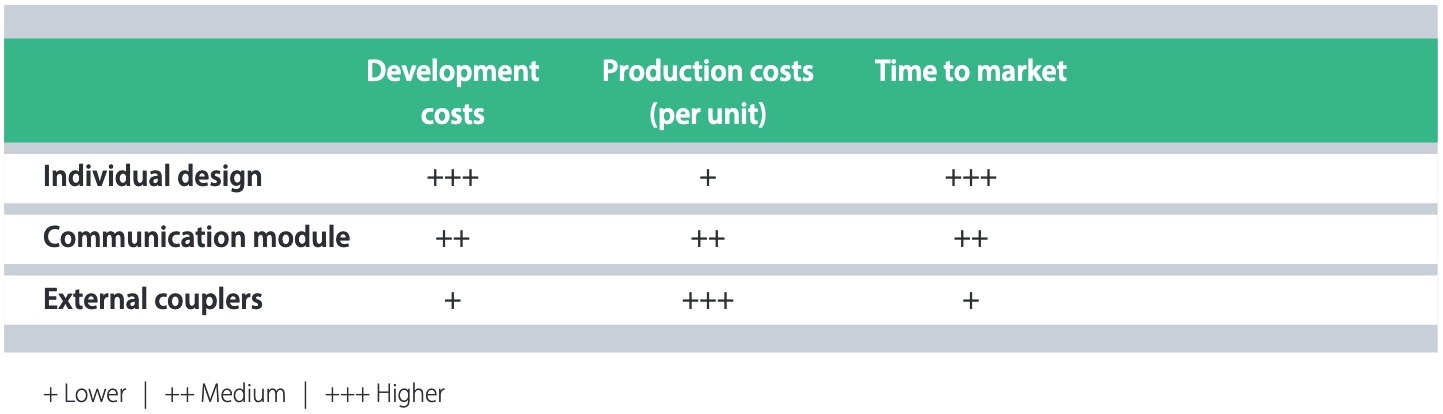

Individual design

The implemented PROFINET interface is embedded in a hardware and software design that has been optimized with regard to development expenditure and time to market using commercially available software solutions and standardized discrete or FPGA-based hardware design schemes.

Communication module

The implemented PROFINET interface is embedded in a design that has been optimized for flexibility and time to market-based on preassembled commercially available communication modules.

External couplers

With this solution, the PROFINET interface is implemented without accessing the device electronics based on external couplers and using an adapter connected in series.

Each of the implementation methods can be realized in a different way. When selecting the most suitable method for the particular case in question, the expected production costs, the development time, and the resulting time to market must be taken into account.

Solution providers

The advantage of collaborating with an external development partner when developing a PROFINET interface is that the product manufacturer can concentrate on its core areas of expertise. This reduces development risks and time to market. The experience of external specialists helps to ensure that the design of the automation device is competitive and technically feasible with respect to its communication technology. This section offers a list of solution providers in North America.

Robust and reliable PROFINET network interface

Analog Devices is the leading global high-performance analog technology company dedicated to solving the toughest engineering challenges. We enable our customers to interpret the world around us by intelligently bridging the physical and digital with unmatched technologies that sense, measure, power, connect and interpret. Our extensive experience with industrial communication and our commitment to industry have led to the development of the RapID Platform Network Interface – a complete, cost-effective, and easy-to-integrate PROFINET connectivity solution.

The RapID Platform network interface manages the PROFINET protocol and network communication for a host processor.

The network interface can be integrated as a module or embedded circuit. It contains everything needed for star, line, and tree network structures, including the communication controller, protocol stacks, Flash memory, RAM, Ethernet switch, and PHYs. The two Ethernet connections can be connected to any PROFINET network. A UART interface, SPI, I2C or std. Ethernet interface can be used for the connection to the applications processor. On the software layer, the host processor is connected to a "Unified Interface" so that other industrial protocols can also be used without having to change the software of the host processor. Thanks to the PriorityChannel® technology of Analog Devices, the network interface has earned PROFINET v2.3 certification for Class B and C devices as well as Net Load Class III approval System start according to v2.2 and v2.3 are both supported so that your field device functions problem-free in any PROFINET network.

Easy hardware and software integration

As a module, the network interface solution can be easily integrated into your own designs. You simply connect a power supply/ground/reset and connect the host processor to selected host interface.

For development of customized circuits, the hardware of the network interface can be integrated based on circuit diagrams contained in the scope of delivery. The scope of delivery also includes the bill of materials and example circuits in order to minimize the hardware development costs. Software for development of customer-specific circuits is provided in the form of firmware, which is downloaded to the Flash memory on the printed circuit board. There is no license fee or user fee, regardless of whether you use the module or an integrated circuit.

Software can also be easily integrated in a host processor. Messages are exchanged between the host processor and the network interface on the basis of a "Unified Interface". A tool provided by Analog Devices that is designed to run on a PC is used to configure the network interface so that you can adapt the necessary parameters of the field devices. The tool also facilitates the adaptation of the GSDML sample file supplied by Analog Devices to your field devices. An additional function of the Unified Interface ensures that the software of the host processor does not have to be changed when PROFINET network parameters change or a different Industrial Ethernet protocol is used. A component of the Unified Interface is a "socket" interface that supports direct Ethernet communication. The scope of delivery includes sample C code so that you can quickly establish a connection between the host processor and the configured network interface

Reliable and flexible network integration

The network interface enables reliable PROFINET communication in conformance with Class B and Class C. PriorityChannel® technology – available only from Analog Devices – is used for this. It eliminates the effects of the network traffic and ensures reliable real-time behavior of the network in accordance with Net Load Class III. This technology provides a significant competitive advantage for your devices, extremely low jitter, and a reliable connection, which will not be disconnected even at a network load of over 95%.

PROFINET support includes optional support of isochronous communication (IRT) the Discovery and Configuration Protocol (DCP) for configuring field devices, and the Link Layer Discovery Protocol (LLDP) for topology management. The scope of delivery also includes the Simple Network Management Protocol (SNMP) and the required Management Information Bases (MIBs) that are used for network configuration and diagnosis. To make commissioning easier, the solution includes a dynamic web server. You can use this web server to create web pages for your field devices that can be displayed on a standard web browser. The network information and real-time parameters of the relevant field device can be updated dynamically at any time on the web page.

Fast integration

The starter kit for the RapID platform network interface enables fast analysis of the circuit for connection of a host processor to the network interface module. The scope of delivery includes an application example that demonstrates the end-to-end communication, i.e., the communication between the host processor and network interface and controller. The Evaluation board allows to connect a host application board on the bench. As soon as communication has been established on the host processor side, the PROFINET communication can be tested with a PLC or controller simulator. This communication can be thoroughly checked before the network interface is integrated in the circuit of the field device.

Future Proof

The RapID platform using the FIDO5000 family of Real-time multiprotocol switches. The fido5000 family is TSN ready and upgardes of the RapID platform to support TSN and PROFINET@TSN are under development.

Contact Us!

5635 Jefferson St. NE, Suite A ♦ Albuquerque, New Mexico 87109 ♦ USA

Phone: 505-883-5263 ♦ Fax: 505-883-5477

www.innovasic.com

PROFINET Stack Integration with Codewerk: We’ll speak PROFINET for you

Support of modern fieldbuses like PROFINET is becoming more and more essential in networked plants. To let your devices speak PROFINET, there are a few things to do:

- Evaluate existing PROFINET ASICs and stacks

- Adapt the stack to your (real-time) operating system

- Implement the interface to your application/host processor

- Implement the GSDML file(s)

- Run integration- and system-tests

- Certify your hard- and software at a PI registered laboratory

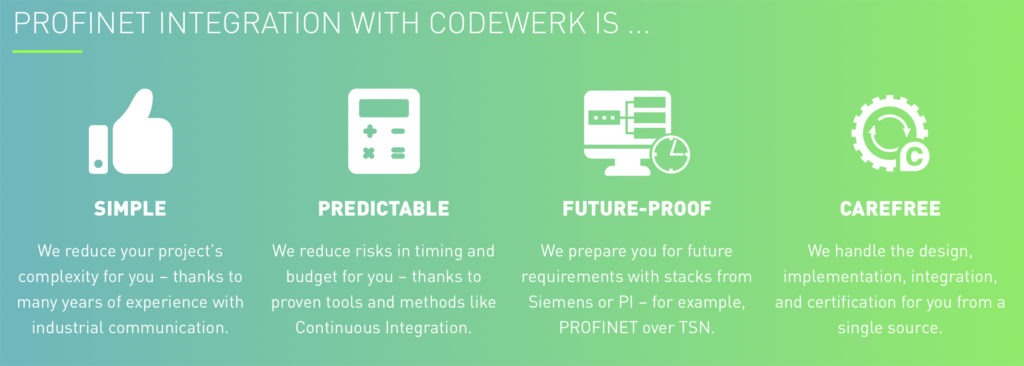

We can handle all these steps as a complete carefree package for you. You can rely on a secure and high-quality implementation – also thanks to our extensive Continuous Integration Framework for builds and tests during development.

What moves you:

As a chip manufacturer, how can you provide the expertise required for testing, integration, and certification of PROFINET – and reliably meet your customers’ time and budget requirements?

As a device manufacturer: How can you expertly integrate existing PROFINET-certified chips and start production on time?

What adds value for you:

With our help, you can return your focus to your core competencies. The Codewerk carefree package covers the entire process of evaluation and integration of an existing PROFINET stack for your chip, platform, and/or (real-time) operating system. The final step is the certification of hardware and software in a laboratory registered with the PI.

We master all of the PROFINET conformance classes, including Class C (IRT) and future Class D (PROFINET over TSN). We are using all official test tools like ART and SPIRTA to pre-test the integration. And it’s possible to integrate individual PROFINET profiles like PROFIsafe, PROFIdrive, PROFIenergy, and PROFIprocess/PA.

What we do differently:

Many things! For example, we give you full freedom of choice between the Siemens PN (PROFINET) stack and the new PI community stack. Each prepares you for future tasks like PROFINET over TSN: The decision is based solely on your requirements. In the process itself, we rely on continuous integration and powerful, automated testing with the Embedded System Integration Check Framework (ESIC). Our goal is to maximize your security of function, time, and budget with our expertise in the field of industrial communication.

Our Know How

- Profound knowledge of the Siemens and the PI Community stack

- PROFINET integration for all conformance classes A, B, C (IRT) and D (TSN)

- Integration of PROFINET profiles like PROFIsafe, PROFIdrive, PROFIenergy, PROFIprocess / PA

- Time-Sensitive Networking integration (TSN)

- Codewerk “Embedded System Integration Check Framework” (ESIC) for continuous integration and automated testing

- Test environment with official PI test tools (ART, SIRTA, Netload)

- Certification mentoring and support

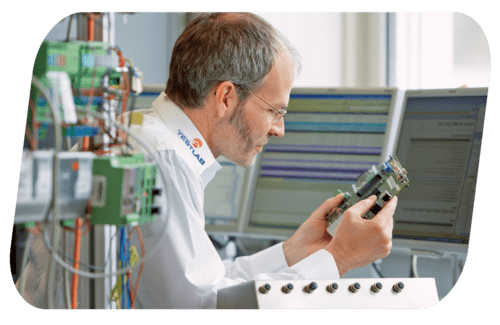

One of our stories

Analog Devices, a global manufacturer of semiconductors, wants to expand its portfolio of multiprotocol Ethernet switching chips. The goal is to provide even broader support for the PROFINET industrial fieldbus protocol and the associated product certifications. This required profound expertise in existing solutions and standards as well as bleeding-edge technologies.

Our collaboration included supplementing PROFINET with isochronous real-time (IRT) support for existing hardware. In this case, we worked closely with our customer to analyze integration options and expand the existing code basis as needed. Key factors in the success of the product certification were the excellent collaboration with Analog Devices, coordinated test runs, our extensive device base, and our PROFINET certification expertise. We also needed to demonstrate how the future PROFINET-over-TSN concept can be integrated in a new switching chip generation. We did this by implementing the first-ever integration of a PROFINET-over-TSN-capable stack on Analog Devices’ new hardware generation.

Contact Us!

Siemensallee 75 ♦ 76187 Karlsruhe ♦ Germany

Email: [email protected] ♦ Phone: +49 721 9841 4678

www.codewerk.de

Hilscher Solutions: From Multiprotocol Chips to Industry 4.0

- netX “system-on-a-chip” multi-protocol network controller

- netIOT Interfaces and netIOT Edge Gateways to add Industry 4.0 functionality

- Coupler, Gateway and Proxy protocol converters

- PC cards for direct connection to networks and controllers

- Embedded solutions for fast integration of network protocols

- Custom PROFINET solutions tailor-made for your devices

- Simple analysis of Real-Time Ethernet networks

Hilscher is a global manufacturer of network connectivity solutions for device makers, OEMs and end-users. At the heart of every Hilscher product is our own netX “system-on-a-chip” network controller, which allows for universal Master and/or Slave connection to all popular industrial communications, including fieldbuses, Real-time Ethernets and IIoT protocols.

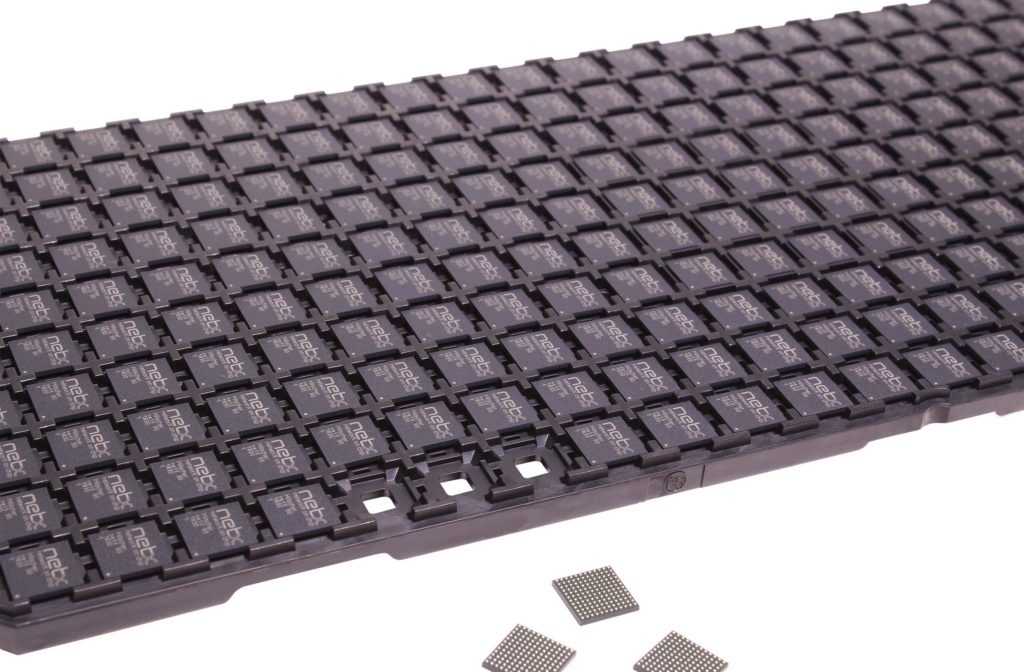

netX 90: Industry’s smallest and most secure network chip for PROFINET and Industry 4.0

The netX 90, a groundbreaking addition to Hilscher’s netX family of multiprotocol SoC’s, is the latest and most advanced connectivity chip yet for slave devices. It comes in a 10mm x 10mm package with a dissipation below 1 watt.

The chip addresses the fact that a large proportion of installed slave devices will have to be replaced or updated if cyber risk threats are to be adequately countered for IT and cloud-based applications. netX 90 has all the built-in security features needed for secure field- and cloud connectivity, including a hardware-based encryption engine, secure boot and a dual-core design for secure separation of application and communication tasks.

In addition to PROFINET I/O device and other Industrial Ethernet and fieldbus protocols, netX90 supports IIoT data communications via OPC UA and MQTT, and offers a comprehensive set of peripherals like EnDat, BiSS and IO-Link.

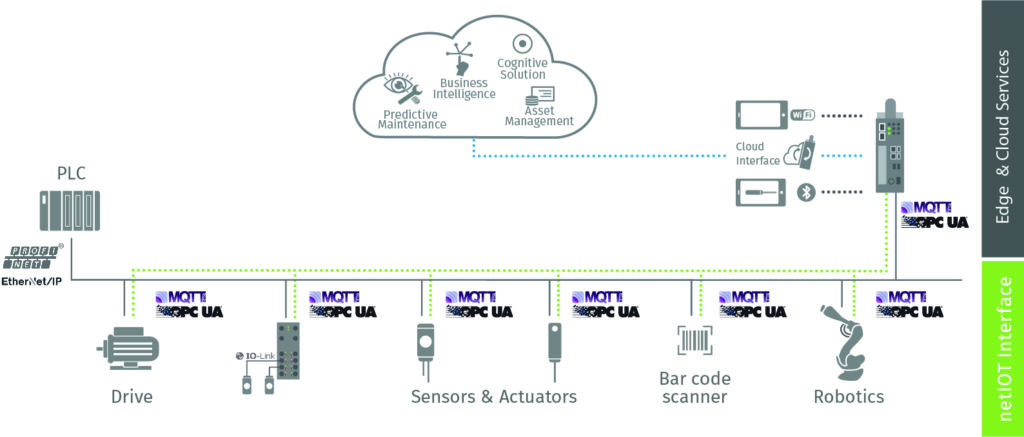

netIOT Solutions: PROFINET and OPC UA for Industry 4.0

To capitalize on the benefits of Industry 4.0 and IIoT, Hilscher has developed the netIOT family of products: netIOT Interfaces for IoT-enabling automation devices and netIOT Edge Gateways for aggregating and processing IIoT data over factory networks.

netIOT Interface is a scalable solution for embedded designs and supports PROFINET, OPC UA and MQTT in compact platforms. Options include the multiprotocol chip netX, the ready-to-solder chip carrier netRAPID and pluggable modules netIC IOT and comX. With these options, manufacturers can easily design Industry 4.0 functionality into their devices. The netIOT Interface software structure allows for multiple channels of communication: cyclic and acyclic I/O data exchange; TCP connection for “transparent” Ethernet; and device specific IIoT data (such as diagnostics) via OPC UA and MQTT.

The netIOT Edge Gateways collect and process Industry 4.0 and IIoT data for business and operational analysis via cloud applications or on-premises. An OEM version of the Edge Gateway allows customization for applications such as predictive maintenance of machines and devices.

Coupler and Gateways: PROFINET connectivity to other networks

Hilscher’s gateway and proxy products are self-contained protocol converters with simple plug-in connections and Master and/or Slave configurations. netTAP gateways bridge fieldbus to fieldbus, fieldbus to industrial Ethernet, such as PROFIBUS to PROFINET, and industrial Ethernet to industrial Ethernet. As coupler, netTAP connects a PROFINET network with a CC-Link IE network via a Slave-to-Slave protocol conversion.

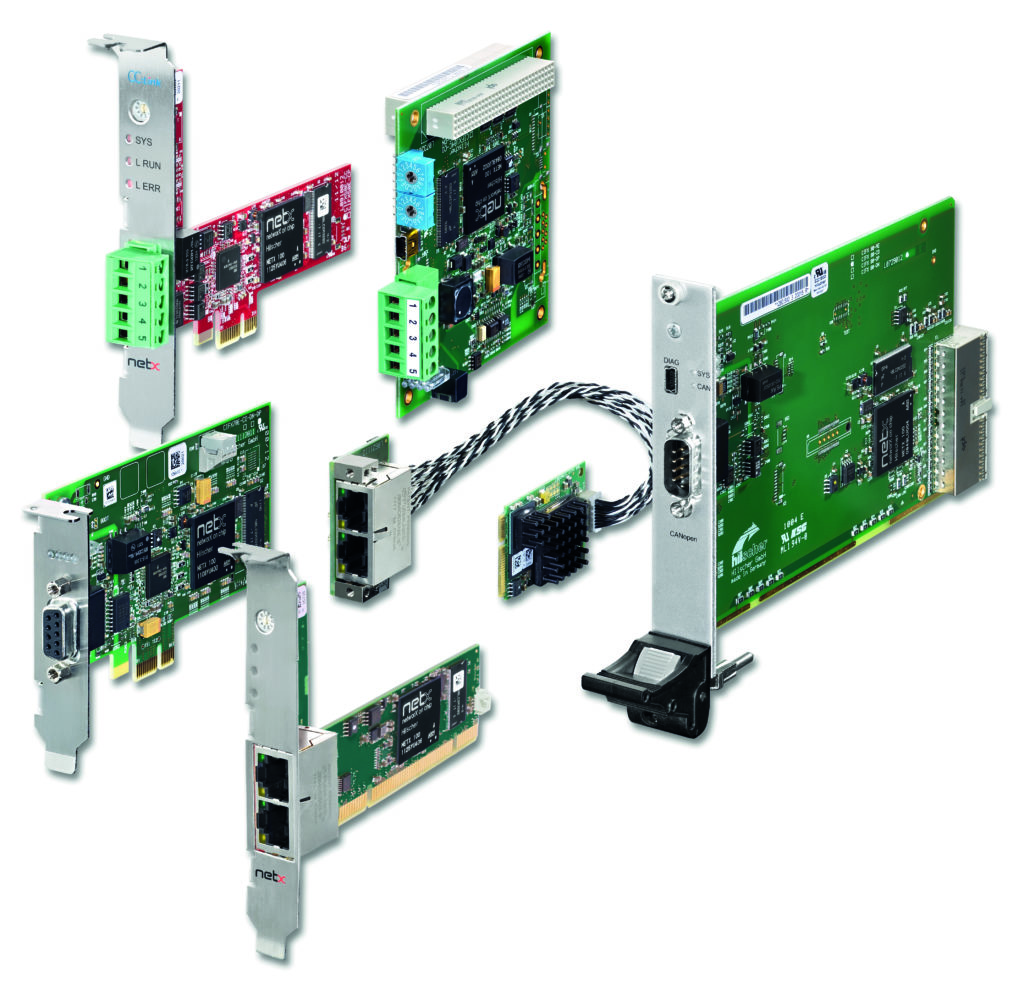

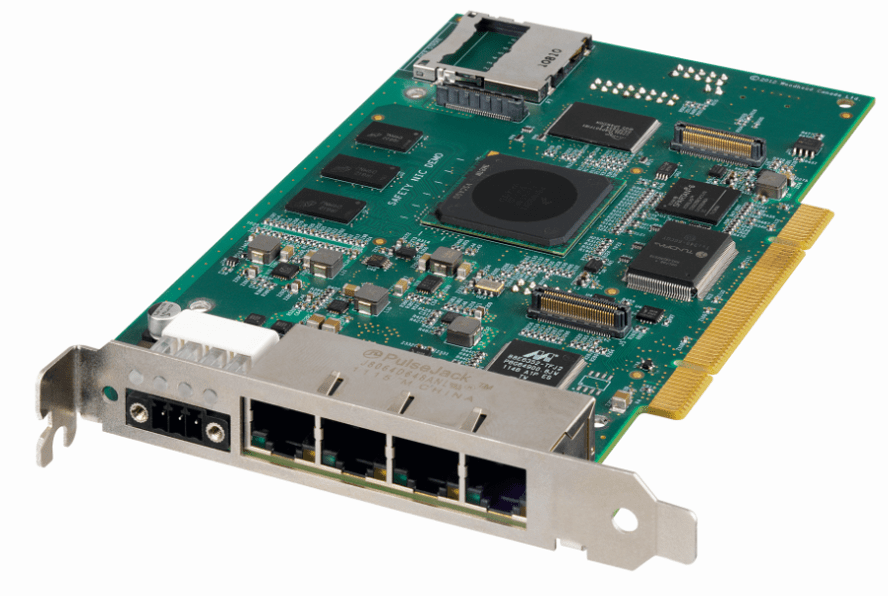

PC-Cards: PROFINET Connectivity and PC-based Controls

Hilscher cifX PC Cards come in all popular PC card formats for direct connection to any industrial network or controller. Besides PROFINET I/O IRT as device and controller, cifX cards support all popular Industrial Ethernet systems and fieldbuses as Master or Slave. Formats include: standard PCI and PCI Express, Compact PCI for cabinet construction, stackable PC/104 and PCI-104, and Low-Profile PCI Express, mini PCI or mini PCI Express. A free C-toolkit and predefined device drivers for Windows, Linux, Intime, VxWorks, QNX and RTX are available.

Embedded Solutions: Easy PROFINET Integration in Field Devices

With Hilscher’s embedded solutions field devices can easily be equipped with a multi-network interface. Besides PROFINET I/O device and controller for highest conformance- and netload-classes, all leading Industrial Ethernet systems and Fieldbuses are supported as Master or Slave.

The embedded products include the netRAPID netX chip-carrier to jump-start your design projects with easy network integration in days, rather than months. The netIC, comX and netJACK option modules allow you to quickly add or change network protocols in a device.

Process data is exchanged via a Dual-Port-Memory, which is accessed by either an 8-/16-bit bus interface, a 50 MHz SPI interface or PCI Express.

Custom PROFINET Solutions: Tailor-made for Your Device

Hilscher offers extensive engineering services to develop custom solutions tailored to your exact specifications. All developments are based on proven netX technology with its comprehensive set of development tools. Contact Hilscher for more information on how we can support your devices and applications.

Contact Us!

2525 Cabot Drive, Suite 200 ♦ Lisle, Illinois 60532 ♦ USA

Phone: 630-505-5301 x225 ♦ Fax: 630-505-7532

www.hilscher.com

HMS Industrial Networks - Connecting Devices

HMS is the leading independent supplier of products for industrial communication, with the product brands Anybus®, IXXAT® and eWON®. HMS products make it possible for industrial machines and devices (hardware) to connect with control systems and Internet (software). Our motto, Connecting Devices™, provides the foundation for realizing the full benefits of Industrial Internet of Things. If you want to connect “Things” to the Internet, you need solutions that enable communication between the hardware and software. This is precisely what HMS offers.

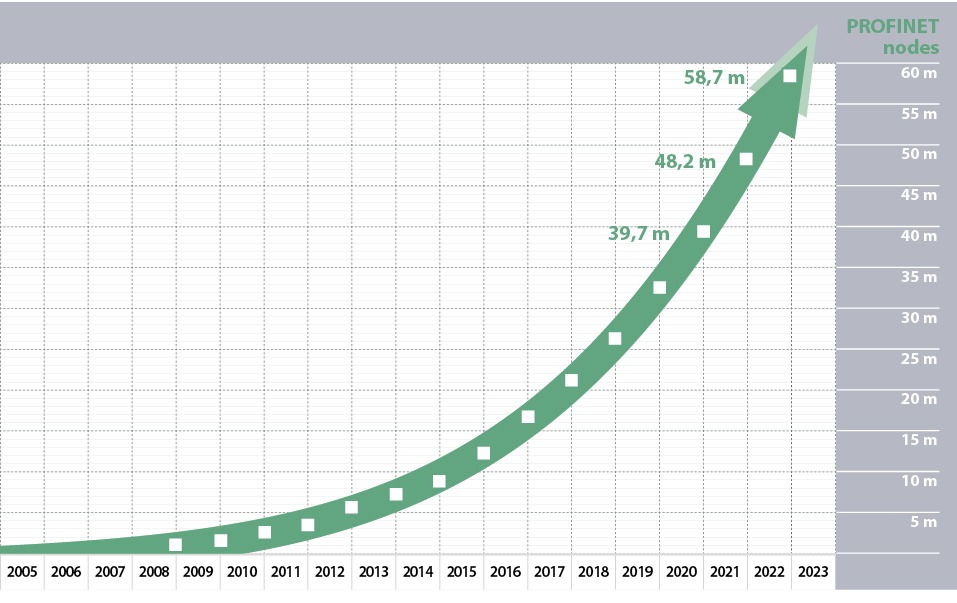

Why it is time to move to PROFINET

The HMS Networks Market Share 2018 report displays that PROFINET has taken 12% of the industrial communication market due to multiple factors. Firstly, PROFINET is built on Ethernet allowing it to support a high node count, faster data rates and larger data packets. It also has the flexibility to be used over a variety of media such as wired coppers, fiber optic cables, and on standard 802.11 wireless connections. This does not require any proprietary wireless adapters, enabling you to mix and match suppliers.

Commissioning a PROFINET device is easy due to plug and play nature of the network. PROFINET devices use auto-negotiation to query and determine the speed and duplex mode of the network. Currently, these parameters are 100Mbps full-duplex. PROFINET devices can also contain one or two Ethernet ports. Devices with dual Ethernet ports have a built-in switch that allows you to daisy-chain other PROFINET devices on the same line. This line topology is like the standard bus topology found in PROFIBUS and can reduce wiring costs compared to a typical star topology. With the combination of the topology discovery feature and other IT features, you can map out your network and have a visual representation of your network topology. This feature allows much quicker diagnostics and can be used to visualize incidents such as wire breaks and loss of communications. Furthermore, this topology does not require the use of additional switches, reducing overall costs.

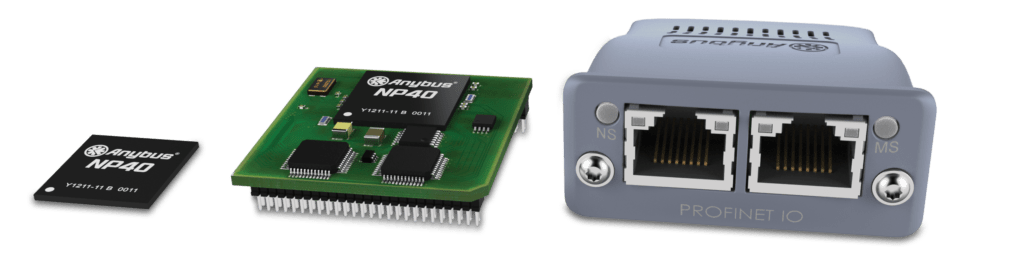

Through Anybus® CompactCom™, you can give your industrial device PROFINET network capability with various physical form factors. Available in Chip, Brick or Module form factors, our cutting edge CompactCom 40 series is based on our award-winning Anybus NP40 network processor. It is ideal for both general purpose and for high-end PROFINET-IRT applications with fast network cycles and synchronization demands. Overall, implementing PROFINET is a great way to ensure your device’s continued success and HMS Industrial Networks is with you every step of the way. Thanks to the help and support of PI (PROFIBUS and PROFINET International), we predict that PROFINET will continue to meet the needs of the automation marketplace and we are creating solutions to help device manufacturers to stay connected.

Contact Us!

35 E. Wacker Dr., Suite 1700 ♦ Chicago, Illinois 60601 ♦ USA

Email: [email protected] ♦ Phone: 312-829-0601 ♦ Fax: 312-629-2869

hms-networks.com

Complete PROFINET Solutions from Molex

Providing more than connectors, Molex delivers complete interconnect solutions for several markets, including industrial automation, automotive and commercial transportation, consumer electronics, data communications, and medical markets. Aiming to advance global Industry 4.0 initiatives, Molex Industrial Automation Solutions add communication and networking to the production process and support the drive toward smarter machines and factories. As pioneers in industrial communication and functional safety, Molex is dedicated to help automation manufacturers & end-users creating value from their factories with technology and products. And our participation for the next industrial revolution with our Molex Industrial Automation Solution 4.0 (IAS4.0) is no different.

Molex PROFINET Solutions

Molex Brad portfolio provides solutions for Automation manufacturers, Machine Builders, Line Builders or End customers to communicate and setup PROFINET infrastructures.

Brad HarshIO PROFINET modules provide a reliable solution for connecting industrial connectors to digital and IO-Link sensors and actuators in harsh environments. Contained in an IP67 rated Housing, Brad IO modules can be machine mounted and are able to withstand areas where liquids, dust and vibrations are present.

Molex Ethernet Network Interface cards provide powerful and reliable real time data exchange over PROFINET protocol. This solution enables PC based control systems like machine or robotic control systems to quickly integrate a certified communication interface with easy commissioning through Molex Network engineering software.

Brad Ethernet switches, cordsets and connectivity products are PROFINET certified, for in-cabinet and on-machine applications complete the total infrastructure offering.

PROFINET Technology and Services

The Molex PROFINET expertise is supplied as PROFINET I/O Development Kits (also called stacks) for automation manufacturers to develop and integrate PROFINET protocol support in their devices. Molex PROFINET stacks are supplied in source code and neutral from any operating system or hardware platform to be adapted to most of the existing device with Ethernet interfaces.

Collaborations with various semi-conductor manufacturers allow Molex to provide a combined IRT version of the PROFINET communication for devices to be integrated in synchronized networks.

PROFIsafe support as F-Host and F-Device is complementing the Molex technology package. This safe communication extension is available, ready to use, based on the Molex IAS4.0 safe platform, for custom integrations and applications.

Molex Industrial Automation Solutions 4.0

Molex IAS4.0 is our answer to the automation transformation that impacts the manufacturing industry in the coming years looking for more flexibility, efficiency and new emerging business models.

Molex IAS4.0 is a revolutionary solution that can distribute intelligence across devices, while also embedding safe and non-safe capabilities into a single hardware/software platform as smart and safe Interface module, Gateway or I/O module.

Molex IAS4.0 is a platform-independent industrial communication solution with the support of the different industrial ethernet protocols, OPC UA or soon PROFINET over TSN, that enables data exchange between products at all layers for seamless sensor to cloud connectivity.

Molex IAS4.0 is a suite of smart products that can be networked with each other and respond to internal and external events with learned behavior and can be deployed in the cloud, on premise and at the edge in a truly distributed architecture.

Contact Us!

2222 Wellington Court ♦ Lisle, Illinois 60532 ♦ USA

Phone: 800-78-MOLEX

www.molex.com

PROFINET Integration & Environment Simulation

In business since 1979, Precision Systems, Inc. (PSI) has designed and developed numerous embedded, real-time, and PC-based mission- and safety-critical industrial systems that cannot fail. PSI has extensive experience developing PROFINET-related solutions including integrations, as well as PSI’s latest product, SIMPLE PN.

Why PSI?

We are committed to helping our clients by increasing their market share through the integration of various protocols, most notably, PROFINET. As the industry continues to adopt PROFINET and roll out more redundant & reliable products, clients recognize the importance of such integration.

Embedded device development is difficult and expensive. Integrating PROFINET in this mix can seem daunting as it is a powerful protocol with numerous applications requiring a high level of understanding. As a PROFINET Subject Matter Expert (SME), PSI is here to help on both the device and controller side. Our extensive knowledge of embedded and real-time systems, as well as redundancy and process control, will be transferred to your project, ensuring a worry-free PROFINET integration.

Product Design & Development

As a device manufacturer, you know your customer’s needs and how to create hardware platforms that satisfy the market. We are intimately familiar with the firmware requirements, design and implementation that brings your control systems, gateways, and I/O devices to life. Working closely with your team, let us help you bring your product to market, built right the first time.

Project Rescue

The occasional technically-strained project can seem insurmountable as challenges of scope, budget, and schedule arise. The source of these issues can trace all the way back to the requirements, or within the overall code design. We have helped numerous great companies get back on track to meet project deliverables as our experience is largely focused on beginning, executing, and completing such projects. If your project needs assistance, we are here to help.

Stack Integration

Have you recently purchased a software stack or are currently looking for one? PSI can help evaluate the right stack for you. Once your stack is selected, PSI can integrate any stack with your existing firmware or with firmware currently in development to add PROFINET functionality to your product.

Project Consulting

Our consulting process begins with a comprehensive assessment of your company’s and clients’ specific needs as well as an evaluation of areas for improvement within your current application. Our goal is to build your project better, faster and more affordably without compromising functionality.

Environment Simulation

In critical environments, users are unable to replicate situations without effecting the active control system, lack appropriate resources to train and onboard employees, and are unable to test in a consistent, predictable way. SIMPLE PN will seamlessly get you over these hurdles.

What is SIMPLE PN?

The short version: PROFINET Simulators

SIMPLE PN is a scriptable, scalable, coordinated, and flexible suite of simulators used to imitate PROFINET controllers and devices. They can be used by device manufacturers, system integrators, OEMs, and end users to create simulated environments for the development, testing, and integration of their devices and systems before, during, and after development.

How will you use SIMPLE PN?

Device Manufacturer – Reliably and repeatedly function and stress test new devices under development with near infinite variety and scale to ensure your devices will perform in any target market environment.

End Users – Simulate controllers and devices, digitally, to envision and mitigate risk on your next factory or line build.

OEM & System Integrators – Simulate the networks and connections on the machinery you design and build, prior to production to anticipate system loads and data flows.

Contact Us!

1355 Business Center Drive, Suite C ♦ Horsham, Pennsylvania 19044 ♦ USA

Email: [email protected] ♦ Phone: 215-672-1860

www.psi-software.com

Software, hardware and engineering expertise

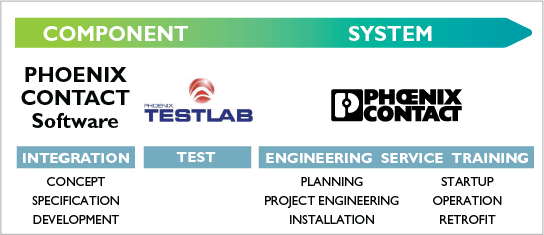

Phoenix Contact is a developer of PROFINET technology and a producer of PROFINET components using this technology. In addition, the accredited Phoenix Contact Competence Center (PCCC), together with PHOENIX CONTACT Software and Phoenix Testlab, offers comprehensive services for all aspects of PROFINET.

For continuous propagation of PROFINET and support for PROFINET users, Phoenix Contact has combined their efforts as a solution provider for automation technology with those of the independent testing and certification institute Phoenix Testlab. Phoenix Contact is an accredited PROFINET IO Competence Center (PICC) with the PROFIBUS user organization (PUO) which includes the profiles of PROFIsafe and PROFIdrive.

Phoenix Contact offers a complete product and service portfolio during the entire life cycle of a device or system – from the specification, technology integration, and certifications of I/O devices including planning, start-up, and retrofit of complex production systems. In addition, comprehensive training programs are offered.

The Phoenix Contact Competence Center:

a complete range of services over the entire lifecycle

from the single component up to the whole system.

Specifications and Development

Phoenix Contact’s PROFINET group supports device manufacturers and solution providers with special products and services during the development phase. High-performance and reliable components are offered for the development of PROFINET IO controllers and devices. Phoenix Contact supports the integration and porting for special requirements in close consultation with our customers.

The PROFINET IO Controller Stack provides convenient context management for the communication connection, Application Relations (AR), as well as comprehensive diagnostics. Extending to a PROFINET IO device component allows quick and direct communication of several PROFINET IO controllers with each other. Typical applications for this are redundant or hierarchically organized automation networks. In order to realize a PROFINET device interface, it is also possible to use only the PROFINET device component without PROFINET controller functionality.

Phoenix Contact will support all project phases during the integration of a PROFINET interface in the form of:

- Concept development

- Technology integration on a wide range of platforms

- Support and Maintenance

- Updates and Upgrades

Concept for a production system: The professionals at the Phoenix Contact Competence Center fully support their customers - starting with qualification measures and continuing with configuration to startup and maintenance of the system.

Protocol testing in the laboratory – the relevant standards form the basis for PROFINET certification tests.

Testing and Certification

As a PI accredited test lab for PR0FINET IO devices, the Phoenix Testlab GmbH in Blomberg, Germany provides device manufacturers with a flexible range of services in all areas required for certification. At the start, all product requirements are validated according to PROFINET standards which reduces "Time-to-Market''.

In order to meet the high quality standards set by our customers, specially developed controller simulation software is introduced as a test system. The PR0FINET I0 test, based on IEC 61158 certification, can be carried out during the development phase or as final test. To ensure the interoperability of certified devices, a multi vendor wall with different controllers and engineering systems is set up as a test assembly. All specified test cases will be carried out by professional engineers.

Planning, Operation and Maintenance of Systems

The services offered by Phoenix Contact Electronics in Bad Pyrmont, Germany are focused on the application of PROFINET products: from planning and configuration during installation, startup and operation, to system modernization.

Contact Us!

Phoenix Contact Software ♦ Phoenix Contact Competence Center (PCCC)

500 Avis Drive ♦ Ann Arbor, MI 48108 ♦ USA

Phone: +1 734-205-5132 ♦ Fax: +1 717-702-4036

www.phoenixcontact-software.com

Phoenix Testlab

Königswinkel 10 ♦ 32825 Blomberg ♦ Germany

Phone: +49 5235-9500 82 ♦ Fax: +49 5235-9500 10

www.phoenix-testlab.de

From gateways to software, custom solutions and training, RTA knows how to move your data

Rely on Real Time Automation to move your data from an automation device to PROFINET IO, or from your PROFINET devices to a variety of other networks, where, when and how you want it.

It’s likely your business isn’t industrial networking, and it shouldn’t be. You make products, design systems, or manage processes. Whatever it is that you make, monitor or install, it inevitably creates data.

Who is Real Time Automation?

RTA is a small, US-based company, keenly focused on helping Control Engineers and Systems Integrators connect automation products to industrial and building networks. Working with 3-person shops all the way up to Fortune 50 companies, RTA solutions can be found in more than 45 countries.

Why Real Time Automation?

After 30 years in existence, we’ve learned the more things change, the more things stay the same. It boils down to creating systems that perform a simple function in an application. Why pay for a Swiss Army knife, when all you need is a butter knife? Many of our competitors create similar products with tons of various features, but it is time consuming learning what each part does. Sometimes, a simple butter knife gets the job done efficiently and pain free. RTA views its products as the “butter knives” of industrial automation. From software to gateways, we have a solution for you to make your job easier.

What makes RTA different?

To be completely honest, you can be successful with any of the solutions in this brochure. Every one of these companies make great products, but we’re unique in that:

- RTA is USA-based. We’re located in the great state of Wisconsin, making our mid-west location convenient for anyone in North America. You may even notice some of our fabulous midwestern accents over the phone!

- We’re a small company of about 20 employees. You can count on your project receiving the utmost attention, more than it may receive elsewhere. Want to talk to the engineer who wrote the code? You got it. Speak to the same support person every time you call? Not a problem. RTA strives to provide the best experience possible and is here to help every step of the way.

- RTA gateways are in stock and ready to ship. Every box will bring a smile to your face and a sense of relief once you realize how easy our solutions are.

From gateways to software, custom solutions and training, Real Time Automation knows how to move your data.

The RTA 460 series easily moves your Profinet data to and from other devices.

Contact Us!

N26W23315 Paul Road ♦ Pewaukee, Wisconsin 53072 ♦ USA

Email: [email protected] ♦ Phone: 800-249-1612

www.rtautomation.com

PROFINET Technology from the Experts

Your only combined certified competence center, training center, test lab in North America

- Do you need to connect your field devices to PROFINET quickly and easily?

- Do you want to gain a PROFINET competitive edge over your competitors?

- Siemens and the PROFI Interface Center can help you from choosing your PROFINET implementation to Certification Testing!

The Right Advice Right from the Start

We can provide comprehensive information on PROFINET technology, implementation and certification. We also offer various trainings and classes for all PROFINET training needs.

Work with the PROFINET experts when it comes to:

- Understanding how PROFINET works, from features to GSDML files

- Choosing the best PROFINET implementation for your product

- Streamline your development and certification process

These PROFINET knowledge offerings are delivered by the PROFI Interface Center (PIC) in North America and by ComDeC (Communication, Development and Certification) in Europe. There are several ways to take advantage of our PROFINET offerings:

- Free webinars on demand

- Free one-day training classes

- Week-long PROFINET Certified Network Engineer classes

- 2-day PROFINET Fundamentals classes

- Developer training on demand

- Customized and on-site training available as well

For more details and training schedules visit our website at: www.ProfiInterfaceCenter.com

The Easy Route to PROFINET implementation

With Siemens’ PROFINET technology solutions you have everything you need to realize a PROFINET field device or PROFINET controller. All our development kits come with the PROFINET software stack and comprehensive documentation to ensure a quick start for your development. Whether you want to integrate a PROFINET RT interface on a standard Ethernet hardware or a PROFINET IRT interface on a dedicated ASIC, Siemens has what you need - free support included!

PROFINET Development Kits (DK’s) from Siemens support a wide range of PROFINET implementation methods:

- Software based: Using our PROFINET RT software stack on a standard microcontroller with Ethernet interface allows PROFINET implementation on existing hardware platforms.

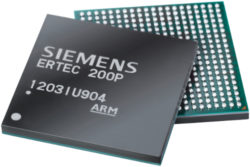

- Hardware based: The ERTEC 200P ASIC offers best in class performance for PROFINET device integration with cycle times down to 125us. Thanks to the on-board ARM9 CPU and an integrated PROFINET IRT switch, a PROFINET field device can be implemented even without an external host CPU. PROIFNET RT and IRT field devices with 2 ports can be realized with the ERTEC 200P chip (Development Kit available).

- PC based: Communication Cards like the CP1625 PCI Express card can be used to implement PROFINET Controller and/or Device functionality on Windows or Linux PC’s (Development Kit available).

The PROFINET driver software allows the integration of a PROFINET Controller interface on a standard PC-based or embedded system (Windows or Linux operating system). The PROFINET configuration can be made by using the license-free version of TIA Portal or the PROFINET-ConfigLib.

For the implementation of fail-safe field devices, a PROFIsafe Starter Kit is available, including the PROFIsafe driver software and an implementation example.

PROFIdrive Reference Implementation and application examples are available free-of-charge for a straight-forward integration of the PROFIdrive profile (AC1 – AC4) in your field devices.

Benefit from a smooth Certification Process

To ensure interoperability of PROFINET products, Certification Testing is mandatory before new devices can be introduced in the market. The PIC is the only PI accredited Test Laboratory in North America. Our 25 years of experience with communication integration and certification testing for field devices will be your advantage.

Your goal is our goal – the successful and efficient certification of your PROFINET product!

Service and Support: Our Experience Helps You to Save Both Time and Money

Siemens provides device manufacturers with the support they need:

- Knowledge transfer

- Development

- Certification

- Phone and email support

Contact Us!

PIC for US and International

Email: [email protected] ♦ Phone: +1 (423) 262-2576

www.ProfiInterfaceCenter.com

ComDec for Europe

E-Mail: [email protected] ♦ Phone: +49 (911) 750-2080 ♦ Fax: +49 (911) 750-2100

www.siemens.de/comdec

Click on a solution provider name above to expand and learn more about their offerings.

Testing & Certification

This section describes how testing and certification work, how to prepare for testing, and how to get a product certified. Also, this guide contains suggestions and resources to complete the certification process with ease.

Getting Started

Certification is the process by which a PROFINET product is tested in a PITL for conformance and, upon successful completion of the testing, issued a certificate by PI.

Products are certified to verify the correct behavior of communication according to IEC 61158 and IEC 61784. Specifically, PROFINET devices are tested for the correct implementation of the following items:

- Hardware interface

- PROFINET mandatory and optional functionality

- Reaction on faulty behavior

- Robustness against netload

- Proper operation in a reference automation environment

- State machines

- GSD file

The PROFINET IO Test Bundle contains a “PROFINET Versions for Certification” document. This document lists the current PROFINET specification and GSD versions. It also indicates the certification testing validity dates for specific versions. The PROFINET IO Test Bundle is available to members at: https://www.profibus.com/download/profinet-test-bundle/.

Passive components include infrastructure components like switches, cables, and connectors, and do not require certification. An exception would be if a switch also functions as a PROFINET device, and has its own GSD file, in which case certification is required.

For passive PROFINET components the conformity must be declared by the manufacturer of the product. These products can then be added to the list of PROFINET Passive Network Components posted on the PI website.

Brand labeling occurs when another vendor resells a device without any change of hardware or firmware.

Brand labeled PROFINET devices need a unique Vendor ID and an updated GSD file. The brand labeling vendor can apply for a certificate based on the original device manufacturer’s test report simply by adding a Manufacturer’s Declaration. The Manufacturer’s Declaration is available upon request from the PICO.

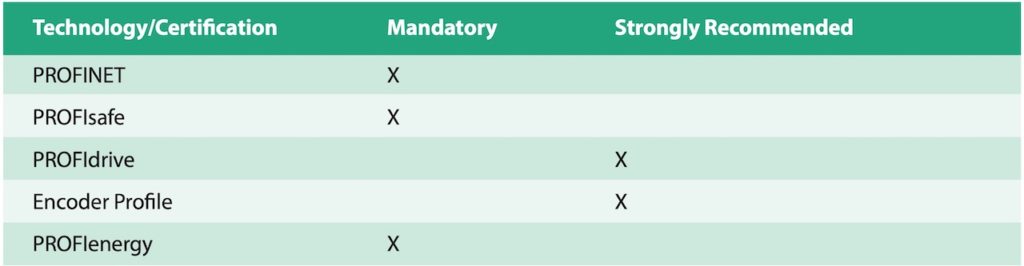

Certification is mandatory for PROFINET devices and controllers. Each product must be certified according to its Conformance Class. Also, some additional PROFINET features, such as the PROFIsafe and PROFIenergy Application Profile, require certification. The table below summarizes the certification requirements:

PROFINET GSD files are written in XML format (therefore sometimes also called “GSDML files”), and they describe a PROFINET device’s functionality. The contents of the GSD file consist of configuration information, parameters, modules, diagnostics and alarms, and vendor and device identification. For certification, the device manufacturer must provide a GSD file for each device.

PROFINET allows for several optional features such as Media Redundancy Protocol (MRP), Isochronous Real Time (IRT), or Fast Start-Up (FSU). If a device supports them as defined in its GSD file, then these optional features must also be certified to verify compliance.

PI does not allow product self-certification. PROFINET components must be tested at a PITL and certified by PI before product launch.

A product certificate shows compliance of a device manufacturer’s product, such as an IO, sensor, drive, or encoder. The certificate proves a device has passed all testing according to the PROFINET standards.

A technology certificate certifies the compliance of a reference design (solution), usually in form of a development or evaluation board, that implements the PROFINET protocol inside a device manufacturer’s product. The chosen solution might be, for example, an ASIC, software stack, module, or plugin board. This certificate shows that the solution intended to be used in the PROFINET device is certifiable according to the PROFINET standards.

Companies that are not members in PI can purchase the PROFINET specification:

- On the IEC website at: https://webstore.iec.ch/

- On the PI website at: https://www.profibus.com/download/literature-list-order-form/

Besides technology specifications, PI offers many free and paid documentation and resources. The following are some commonly used (member-only) development resources:

- PROFINET IO Test Bundle

- PROFINET GSD Checker

- Application Profile Specifications

- Test Specifications

PI members have full access to all standards, guidelines, specifications, software, resources, and documentation at no charge. PI members can obtain the PROFINET specification at no-cost as a membership benefit. Upon joining PI, members are issued a company-wide login with rights to these downloads. The full PI documentation and resource list is available at the PI download center: https://www.profibus.com/download/.

All PROFINET components have two associated IDs: A Vendor ID and a Device ID. Device manufacturers must obtain a Vendor ID and define a Device ID before testing since both IDs are included in the device’s GSD file.

Vendor IDs are unique, and therefore managed and assigned by PI to each company. Device manufacturers can obtain their PROFINET Vendor ID at no charge by sending an email to: certification{AT}profibus.com. Vendor IDs are the same for PROFIBUS, PROFINET, and IO-Link. If a device manufacturer already has a Vendor ID for PROFIBUS, there is no need to request a new one for PROFINET.

The Device ID is chosen and managed by the device manufacturer. Each device should have a unique Device ID specifically for the device. The “GSDML Technical Specification for PROFINET” document in the PROFINET IO Test Bundle contains details about Device ID formatting.

Since the PROFINET specification is open and standardized, anyone can build and sell PROFINET products; a PI membership is not required. However, joining the membership is beneficial, especially during the development process. The affiliation gives members access to the aforementioned downloads along with cost reductions for training and certificates, among other benefits.

Companies become a PI member once they join an RPA. Companies can choose to join multiple RPAs since each RPA offers unique local marketing and training opportunities. PI North America is the North American RPA. Among other benefits, PI North America members can participate in comprehensive marketing programs. To join PI North America, an application form can be submitted at: https://us.profinet.com/membership/become-a-member/.

Before Certification Test

The same tools and software used by PITLs for testing are also available for free to PI members as part of the PROFINET IO Test Bundle.

The PIC also offers a “pre-test”, an abbreviated test that covers the most critical parts without going in depth. The result indicates a list of issues to resolve before the actual test. The pre-test is recommended for first-time applicants or new/complex devices.

To begin the process, the device manufacturer must fill out and sign the standard test application form. As part of it, they must specify all supported application types, features, and Application Profiles. The PIC test application form can be found at: https://profiinterfacecenter.com/testlab/forms/.

It is also recommended to send the device’s GSD file together with the completed test application form. Based on the completed test application form and GSD file, the test length and cost can be calculated. Then, the PIC can provide a quotation if required. The final step to book the test is to send a Purchase Order (PO). Once the PO is accepted, the PIC will schedule and confirm the test date based on the device manufacturer’s requirements and the PIC’s schedule.

The length and cost of testing depend on the supported features, device complexity, variants, and other factors. For example, a simple device takes about three days of testing; a complex device family can take up to two weeks.

The PIC test application form includes a fee schedule as an initial estimate. The PIC can provide a final quote after receipt of the completed test application form and associated GSD file.

The information provided in the completed test application form will be reflected in the eventual test report and shown on the official certificate. The device manufacturer should submit the completed test application form in their name, even if they work with a third-party developer. The manufacturer can also choose to endorse a third party allowing the PIC to work with a third-party developer during the test. The PO can come from either party.

As a recommendation, the device manufacturer can start the application process as soon as they can forecast the end of development or internal testing. The PIC test application form contains a field to specify the “earliest test date”.

Lead times in the test lab depend on lab availability and vary from ‘immediately’ to several weeks out. Device manufacturers can obtain the current lead time by contacting the PIC directly.

The customer must contact the PIC immediately when schedule changes arise. The PIC coordinates closely with device manufacturers to reschedule test slots.

Testing a PROFINET controller is similar to testing a PROFINET device. The test application form has extra fields to provide controller-specific information. The PIC offers a controller test information bundle which will be provided after receipt of the completed test application form.

During Certification Test

It is possible to certify several “variants” of a device along with the representative device. Variants usually differ in terms of application features (number of IO modules, etc). The variant list must be included in the completed test application form.

While not required, it is recommended that a representative from the device manufacturer’s team attends the test for the first one or two days. Having a representative on hand helps to quickly resolve issues that arise during testing. If issues cannot be resolved, the representative can learn to reproduce the issues outside of the test lab. This is especially true for customers completing their first PROFINET project or submitting a complex device for testing.

Once the device has passed the testing, the PITL sends an accredited test report to the device manufacturer.

It is important to know that PITLs do not issue certificates directly. The device manufacturer will use the test report to apply for the actual certificate from the PICO.

After testing, the PIC can send the device back to the device manufacturer. The device manufacturer must indicate a carrier account number on the completed test application form or send a prepaid shipping label with the product.

If the device manufacturer does not need the device back, the PIC will repurpose and add it to its integration test network to use in future tests and to showcase the variety of devices available.

The PIC provides the following power supplies in its test lab. If the PROFINET device requires additional power supplies, they should be sent along with the sample device for testing.

- 24VDCforcurrentdrawupto10A

- 120V/60HzAC1Pforcurrentdrawupto10A

- 240V/60HzAC1Pforcurrentdrawupto3A

- 230V/50HzAC1Pforcurrentdrawupto3A

The PIC can supply the following network cabling in its test lab. If the PROFINET device requires additional cables, converters, PoE or interface types, they should be sent along with the sample device for testing.

- RJ-45 / 4 conductor

- RJ-45 / 8 conductor

- M12 / D-Coded / 4 conductor

- M8 / D-Coded / 4 conductor

Normally, sending one device for testing is sufficient.

If there are several variants, the PIC and device manufacturer will discuss before the test which ‘main devices’ (full test) and ‘variants’ (partial test) require testing. Usually, not all variants need to be tested.

Also, even with just one main device, it can be beneficial to send more than one device. For example, some tests can run in parallel, or the testing can continue if one device locks up.

The best option is to supply the PROFINET interface component along with a system simulator that runs a full implementation of the application software without the large, heavy, or power- hungry physical apparatus.

Another alternative to certify the device is to inquire about on-site testing services. For example, PITLs are allowed to perform an on-site test if the device meets one or more of these criteria:

- Device or any device part exceeds the maximum transport size of 1800 x1500 x 700 mm

- Total transport weight of the device is greater than 300 kg

- Device utilizes or is technically possible to adapt it to utilize input power higher than 32 A, 400 V AC, 50 Hz, or corresponding values for countries outside Europe

Each PITL has different strategies when reporting issues with a device during testing.

For example, the PIC will report minor issues back to the device manufacturer as they happen while continuing to test other aspects of the device. Once the PIC receives a fix, they will verify the issues are resolved. For major issues (hardware/performance/stack issues), the PIC can put the test on hold and resume after receiving the updated device.

The certification test should not be seen as a pass/fail test. The PIC and the customer have the same goal: to have the device successfully certified.

After Certification Test

After testing, the device manufacturer will receive a test report from the PITL. To obtain the certificate, the device manufacturer must send the positive test report and a completed certificate application form to the PICO: https://www.profibus.com/download/application-form-for-a-certificate/.

The certificate costs 1800 EUR for PI members and 6000 EUR for non-members.

The granted certificate is valid for three years. It can be prolonged if specific criteria are met.

The Product Finder on profibus.com is a central repository where end-users search for PROFIBUS and PROFINET enabled products. As a member benefit, PI members can add their products to the Product Finder.

It is the manufacturer’s responsibility to add and update their product information.

To add new entries to the Product Finder or edit existing entries, members must log in to: https://www.profibus.com.

The rights to use the Association Trademark and Technology Trademarks are acquired through membership. Member companies can use these logos as part of the marketing of their products or simply to display support of PI’s technologies.

The Certification Trademark can be used to identify products certified by PI. The right to use the Certification Trademark terminates automatically if the product is modified and no longer satisfies the established test criteria.

The device manufacturer can request to prolong the validity of a certificate. The request must be made within three months prior to, and three months after, the certificate‘s expiration date. For this purpose, the device manufacturer must send a completed certificate application form and a Manufacturer’s Declaration to the PICO.

The declaration must contain the following statements:

- Declaring the unchanged conformance of the product with the tested prototype in hardware and software per the latest test report.

- Declaring there is no newer version of the device that uses the same device identification, i.e., Vendor ID, Device ID, or DAP-Module-ID.

Otherwise, the prolongation of a certificate requires a retest.

Device Manufacturers can update a GSD file to a new version by ensuring compatibility with the old version under their own responsibility. Then, the device manufacturer must submit a statement directly to the PICO. In any case, the device manufacturer is responsible that at any time, only one valid GSD file exists for a product. If the device manufacturer wants to update their certificate with a new GSD file name, they must contact the PICO to obtain an updated certificate.

Product modifications invalidate the certificate. Depending on the modification, the PICO can update the certificate via a Manufacturer’s Declaration, a new test report, or a positive statement from a PITL.

Some product changes only require a Manufacturer’s Declaration; other modifications require partial or full retesting. For example, changes in the communication interface or firmware modifications require retesting. Contact a PITL to assess the retest requirement.

Partners for Product Testing and Certification

PI is the creator, maintainer, and promoter of open, industrial communication standards such as PROFINET and PROFIBUS.

T: +49 721 9658 590

E: question{AT}profibus.com

W: https://www.profibus.com

The PICO issues and updates product certificates. They also provide support for the certification process and issue Vendor IDs.

T: +49 721 9658 586

E: certification{AT}profibus.com

W: https://www.profibus.com/products/certification-office/

PI Test Laboratories (PITLs) are test centers authorized by PI to execute certification tests on PROFIBUS and PROFINET products. There are currently nine across the world in major industrial countries.

The PIC is a PI accredited test lab, competence center, and training center for PROFIBUS and PROFINET, located in North America.

T: +1 423 262 2576

E: PIC.industry{AT}siemens.com

W: https://profiinterfacecenter.com

Regional PI Associations represent PI around the world. RPAs act independently to support PROFIBUS and PROFINET in their own region.

W: https://www.profibus.com/pi-organization/regional-pi-associations

PI North America is the RPA responsible for the North American region. Also, they are a non-profit, member-supported organization.

T: +1 480 483 2456

E: info{AT}pinorthamerica.com

W: https://us.profinet.com

We can help!

Contact us directly for more information on PROFINET development. We can also connect you with the solution providers listed above. Please fill out the form below and we will get back to you shortly.