The second session I attended in the Industrie 4.0 meets the Industrial Internet forum was by Armin Pühringer of Hilscher. I was attracted by the title, “From Sensor to Cloud – Device Integration and IT Infrastructure.” Knowing that Hilscher has introduced products for moving PROFINET data to the cloud and given PI’s cooperation with OPC to use OPC UA to complete the data’s journey, I thought this session would be very interesting. It was.

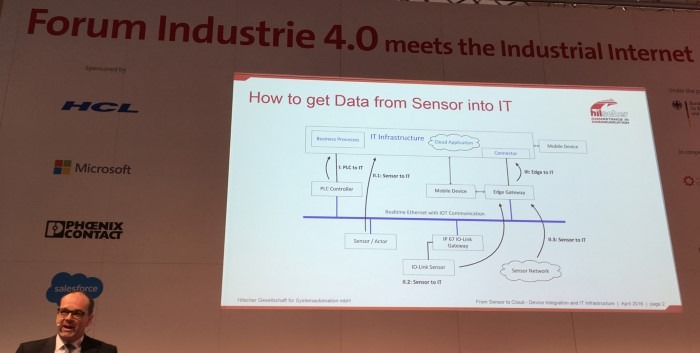

Armin proposed four paths that data could take from sensor to cloud (enlarge the picture):

I. Industrial Ethernet >> PLC >> cloud

II.1 Device (Sensor or Actuator) >> cloud

II.2 IO-Link sensor >> edge gateway (III) >> cloud

II.3 Sensor network >> edge gateway (III) >> cloud

I had been considering the PLC route the most common (I) followed by device to cloud (II.1). Sensor network through an edge gateway to the cloud (II.3, III) makes sense though; think PROFIBUS, FF, AS-interface, etc. I still struggle to understand IO-Link’s route to the cloud (II.2, III).

Fortunately, I was able to spend some discussion time with Armin (and Hilscher North America’s Phil Marshall) to clarify his four paths. The PLC route which seemed the most likely to me does have limitations. On the plus side the PLC adds value to the data and adds data. The PLC is after all performing logic, combining inputs, adding counters and timers, and potentially buffering some data. The down side is that the PLC may not be powerful enough to convey all the data that needs to get to the cloud. In our PROFINET one-day training classes we represent the need for an alternative path (Armin’s path II.1):

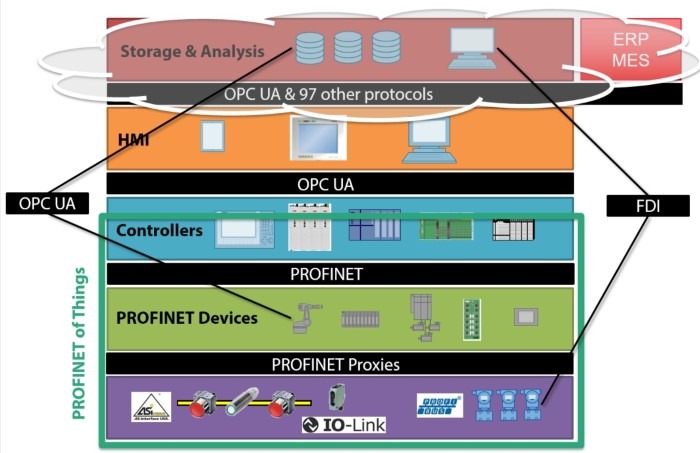

This architecture shows that some devices (more complex devices) like robots, drives, and instruments can connect both into the controller via PROFINET and to the cloud via OPC UA. The beauty of Ethernet is that multiple applications can run at the same time over the same infrastructure, so PROFINET and OPC UA (since they both use standard IEEE Ethernet) can share the same cable.

The sensor network could be connected via an edge gateway (II.3, III) or (not shown) through a PROFINET proxy to integrate it into the PROFINET network and from there to the cloud. The IO-Link approach outlined strikes me as difficult since IO-Link devices have limited computing power. It would make sense to me if the arrow on his slide was from the IO-Link Master to the edge gateway to the cloud. Of course with PROFINET it could also connect through PROFINET to the PLC and up from there. Paths not through the PLC are needed if the PLC cannot handle the amount of data. You always have to do the engineering – determine for your specific project which path or paths make sense.

My conclusion is that Armin’s proposed paths parallel what we have been saying. PROFINET to controller to cloud while recognizing that a path is needed that skips PROFINET for some data-intensive devices. And the two paths share the same cable.

–Carl Henning