0

NodesPROFINET growth continues to accelerate year over year across all industry verticals. Read about the technology below that fuels this success.

§1.0 – PROFINET What & Why

PROFINET is the world’s most advanced Industrial Ethernet solution. It is a communication protocol to exchange data between controllers and devices. Controllers can be PLCs, DCSs, or PACs. Devices can be I/O blocks, vision systems, RFID readers, drives, process instruments, proxies, or even other controllers. PROFINET is fully compatible with – and leverages all the features of – office Ethernet. However there are differences, office Ethernet is not capable of real time performance for industrial automation. Office Ethernet is also much less able to withstand harsh industrial environments.

§1.1 – Real Time Performance

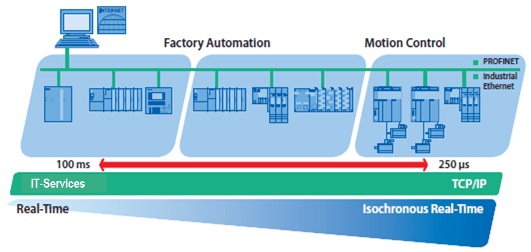

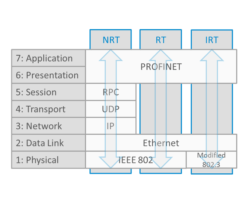

PROFINET meets the demands of IT and plant floor automation using three communications channels:

- Standard TCP/IP: Suitable for non-deterministic functions such as parametrization, video/audio transmissions and data transfer to higher level IT systems.

- Real Time (PROFINET RT): TCP/IP layers are bypassed in order to have a deterministic performance for automation applications in the 1-10 ms range. This represents a software-based solution suitable for typical I/O applications, including motion control and high-performance requirements.

- Isochronous Real Time (PROFINET IRT): Signal prioritization and scheduled switching deliver high precision synchronization for applications such as motion control. Cycle rates in the sub-millisecond range are possible, with jitter in the microsecond range. This service requires hardware support in the form of (readily-available) ASICs.

§1.2 – Different from Office Ethernet

As fieldbus adoption grew, users realized that tighter integration with IT would become more and more important. Fieldbus systems can be integrated into plant networking hierarchies using gateways and other devices but that approach can be cumbersome and expensive. Therefore, users wondered if office networking technologies – i.e. Ethernet – could be brought onto the plant floor. The ideal scenario, they argued, was for automation systems themselves to be based on Ethernet.

§1.3 – Fieldbus: What & Why

Fieldbus is a digital industrial networking technology for transporting data between control devices (such as a PLC or DCS) and field devices (such as I/O, drives, actuators and transmitters) for the purposes of controlling production lines and equipment. By improving communications between these devices, a fieldbus facilitates significant improvements in the way plants are controlled, monitored and managed in both process and factory automation environments.

§1.4 – Coexistence

Because PROFINET is fully compatible with office Ethernet, it can reside (and be fully operational) on a single network cable alongside other Industrial Ethernet’s that are also based on standard Ethernet. There are several of these, including EtherNet/IP and Modbus/TCP.

§1.5 – Free Training across North America

Over 16 free one-day training classes for PROFINET are given across North America throughout the year. They serve to educate and assist in all technical aspects of using the PROFINET. The class is specifically designed for end users, machine builders, system integrators and manufacturers of automation devices. All students receive a training manual that includes a hard copy of presentations plus additional documentation in network design, installation, commissioning, and security guide manuals.

§2.0 – Features

PROFINET was developed by PI Working Groups involving over 500 engineers from major automation vendors. Their vast field experience with PROFIBUS was used as the starting point. Ethernet’s particular attributes were then selectively incorporated to meet the specific needs of automation.

§2.1 – Handling I/O

PROFINET treats I/O very much like PROFIBUS does. An engineering tool is associated with the controller and obtains information about the IO Devices from a GSD file just like PROFIBUS does. After a project is configured in the software, it is downloaded to the controller. The controller can then communicate with the I/O Devices. The I/O Devices are structured hierarchically as Device, Module, and Channel. Inputs and Outputs are exchanged between the controller and I/O Device as ‘cyclic’ data. The controller sets the update cycle time. Additional information such as diagnostic data that is not required as frequently is communicated as ‘acyclic’ data.

§2.2 – Wireless

Wireless is part of PROFINET’s specification for two well established wireless standards: Wi-Fi and Bluetooth. The use of standardized wireless technology has no restrictions compared to normal cabling. Also, PI is active in helping standardize wireless networking solutions for industrial applications in both Process and Factory Automation arenas.

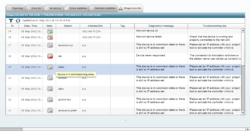

§2.3 – Diagnostics

PROFINET offers an unprecedented level of diagnostics capability, both locally and remotely using standardized displays.

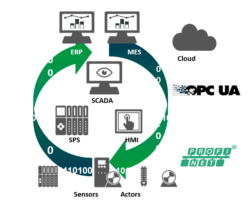

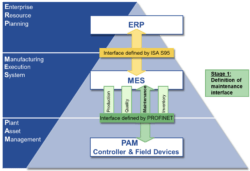

§2.4 – Vertical Integration

PROFINET is fully compatible with standard Ethernet, hence it can provide classic TCP/IP performance whenever required. Consequently, it is easily scaled to match the needs of almost any size manufacturing facility. In addition, PROFINET networks are easily integrated with existing Ethernet networks such as higher level enterprise systems including MES and ERP (Manufacturing Execution Systems and Enterprise Resource Planning). Within reason, and working within your own security and management strategies, it is possible for PROFINET to reach across the enterprise.

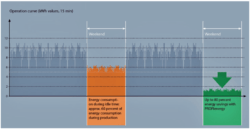

§2.5 – PROFIenergy

PROFIenergy offers a completely new way of saving energy in automation systems. With PROFIenergy, automation controllers on a PROFINET network determine when end devices are switched into ‘sleep’ or OFF modes to save on energy usage during:

- Expected short breaks – e.g. lunchtime and shift changes

- Planned longer breaks – e.g. nights and weekends

- Unplanned pauses – e.g. breakdowns, maintenance, and upgrades

§2.6 – Fast Start-Up

PROFINET Fast Start Up (FSU) feature allows IO Device to go instantly into a ‘power on’ state in response to signals from an IO Controller. Such functionality is a high priority for industrial robots with Automatic Tool Change (ATC) since it can increase the flexibility of production lines and reduce the number of robots per cell.

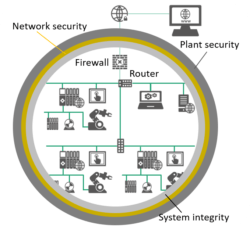

§2.7 – Security

The openness of Ethernet guarantees easy access from anywhere in the world using readily available tools such as web browsers. This great advantage has implications for the security of networks across the enterprise.

§2.8 – Safety

Safety systems protect equipment, people, and the environment. Traditionally, they rely on separately wired circuits that are expensive to build, commission, and maintain. Nowadays functional safety can be done over the bus shifting from safety in hard relays to safety in logic. Adding functional safety to an existing automation network means less engineering effort, reduced cabling, faster commissioning and easier maintenance. Networked safety systems also offer greater flexibility, safety strategies can be easily zoned, partitioned, and changed. Innovative safety architectures become possible with new generations of safety devices such as laser scanners.

§2.9 – Simple Device Replacement

Automation networks are built to run continuously for many years. But, over long periods, automation components can fail or get damaged. The Simple Device Replacement feature is unique within the industry. It allows users to replace PROFINET devices in a fast and effortless manner.

§2.10 – Process Automation

PROFINET is often used in process plants as the main network backbone, but PROFIBUS PA is still used where no Industrial Ethernet can go – into hazardous areas. Not a limitation of PROFINET, but a limitation of Ethernet, since Ethernet was never designed as a hazardous area network.

§3.0 – PROFINET Project

Designing and engineering a PROFINET project is straightforward, especially if you already have fieldbus experience. Migrating from a fieldbus to Industrial Ethernet is particularly easy. Even those who don’t have any experience should rapidly pick up the theory and practice of PROFINET. In this section, we’ll talk you through the basics. Our Resources will then give you all you need to understand what to do and how to do it.

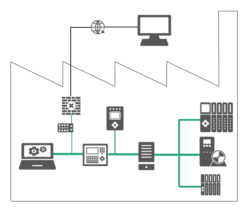

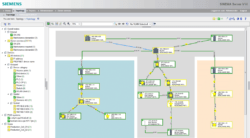

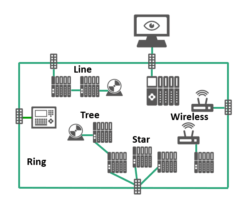

§3.1 – Designing

Ethernet is a highly scalable and versatile communications technology. It can be deployed in line, tree, tree and branch, star and ring architectures and both IO and peer-to-peer communications are possible.

§3.2 – Selecting

To ensure the highest quality performance and to guarantee interoperability it is a mandatory requirement that all PROFINET products are certified. Only in that way users can have full confidence in their purchases. A list of products can be found in the Product Finder on the main PI website; NOTE: it is the responsibility of the manufacturer to maintain the listing of their products there! If a product cannot be found as such, it does not necessarily mean the product has not been certified. Check with the device manufacturer for a certificate.

§3.3 – Installing

Rugged RJ-45 connector

Standard ‘best practice’ in cable installation and maintenance should be followed at all times. Here are a few installation tips that should be borne in mind:

§3.4 – Commissioning

There are many resources that you can call on to help with commissioning…

§3.5 – Maintaining

Standard Ethernet has a set of diagnostic tools and protocols that will be familiar to office-based technical personnel. These can be utilized in the industrial environment to provide detailed information about lower-level transport-oriented issues such as TCP, UDP and IP activity. They can also support statistical and connection analysis.

§4.0 – Migrating from PROFIBUS

If you have PROFIBUS networks already installed, or if you’ve got PROFIBUS skills available in your plant then migrating from PROFIBUS to PROFINET will be quick and simple. That’s because the Working Groups which developed PROFINET drew heavily on the experience of PROFIBUS. For example, if you’re familiar with GSD files for engineering you’ll be familiar with the GSDML files used by PROFINET. Likewise, the diagnostic functions. Also, many of the PROFIBUS profiles – for example, PROFIsafe and PROFIdrive – will also be familiar.

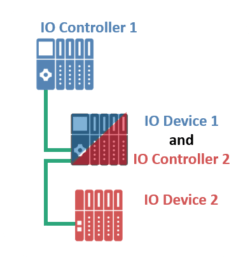

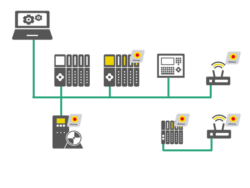

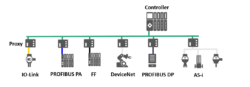

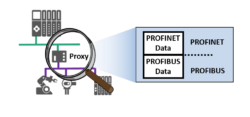

§4.1 – The Proxy Concept

A PROFINET ‘proxy’ is a black-box interface sitting between PROFINET and a sub-network such as PROFIBUS. It differs from a conventional gateway device in that it maps the underlying protocol to PROFINET. This allows a controller on the PROFINET network to access devices on the sub-network with ease because all functions and services are directly available without further interpretation.

§4.2 – Proxy Devices

Remember, a ‘proxy’ is a special interface for connecting PROFINET to lower level networks such as PROFIBUS, INTERBUS, etc. A proxy differs from a standard gateway or bridge in that acts as a sub-network master and a PROFINET slave simultaneously. The underlying protocol is therefore mapped directly to PROFINET and the PROFINET controller ‘sees’ the sub-network as remote IO. Proxies are part of the PROFINET specification.

§4.3 – Migrating to PROFINET

Many of the design, engineering and deployment issues for PROFINET resemble those of PROFIBUS. However, PROFINET offers additional capabilities.

§4.4 – PROFINET Features vs. PROFIBUS

PROFINET offers much higher performance than PROFIBUS and other fieldbuses in terms of:

- Unlimited scalability

- Unlimited address space

- Larger message size (1440 bytes vs. 244)

- Machine 2 Machine (M2M) communication

- Vertical integration capabilities

- The possibility to coordinates more drive axes (32 axes vs. >150) – with IRT updates in 1 ms range, with less than 1 us jitter

- It’s faster too, which means more application potential and fewer interfaces

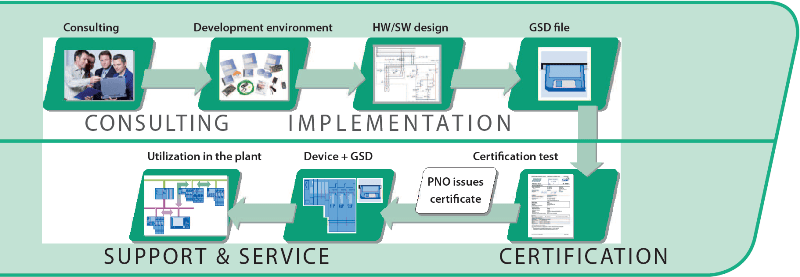

§5.0 – Product Design Cycle

Content from this section can be found in The Easy Way to PROFINET White Paper.

Scroll down for a step by step guide to implementing PROFINET.

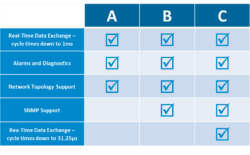

§5.1 – Consultation

PROFINET has core functionality that defines how data is transferred within a network. This relies on basic Ethernet standards such as TCP, UDP, DHCP, SNMP, LLDP, IP, and MRP. To this core functionality are added a set of options which deliver the full Industrial Ethernet experience. The basic industrial automation services are TCP/UDP IP, for general data transfer; PROFINET real time (RT) for a broad range of IO applications including drives; and PROFINET isochronous real time (IRT), for advanced motion control.

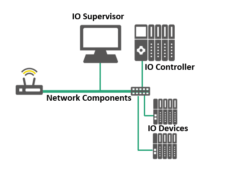

§5.2 – Device Type

Node Class

A PROFINET network is composed of different types of components. Each component performs different tasks, generally, they are described in four node classes.

READ MORE...

§5.3 – Device Functionality

Communication Class

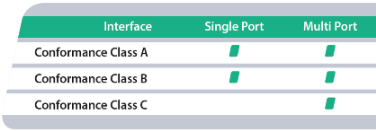

After determining the node class of the device, it is important to know where the device will be deployed so that it can effectively communicate with the necessary speed.

§5.4 – Device Options

Incorporating PROFINET into your device means modularity and flexibility. Start simple and add functionality as required. There are features that some manufacturers will desire to be integrated, and others will not. Some examples of these optional modules include:

§5.5 – Development Environment

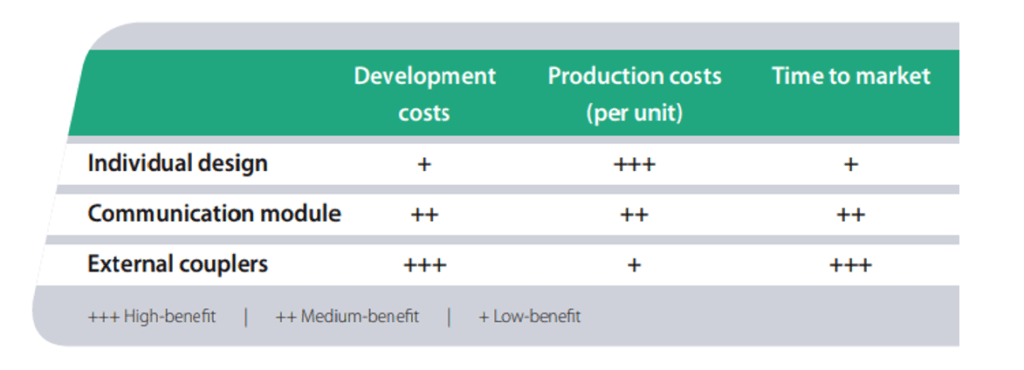

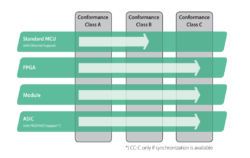

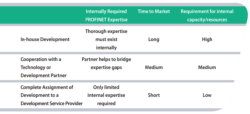

When choosing the format by which PROFINET will be integrated into a device, it is mainly dependent upon the eventual goals and applications of the component. Different solutions exist for this; broadly they are:

§5.6 – Development Functionality

Not all development environments are capable of handling every conformance class. Certain devices will require hardware and software that will enable it to perform in its desired application. For example, the requirements of conformance class C mean that devices have a multi-port interface:

§5.7 – Hardware / Software Design

Hardware and software design can pose special challenges and if you do not have in-house resources, you may need to find a supplier to help. A modular solution may well suit your needs if numbers are small. Flexibility is an additional benefit in these circumstances. Maybe your volumes justify a special board design, or custom product. The advantage of collaborating with an external technology or development partner when developing a PROFINET interface is that the device manufacturer can concentrate on its core areas of expertise.

§5.8 – Certification Test

Conformance testing and certification are mandatory for all PROFINET devices to guarantee interoperability. It is also the primary factor influencing customers to buy PROFINET products.

§5.9 – Release Product

Once your device is certified, it is now ready for the market. Make sure your package is complete, including sales literature and web presence. Also, make sure your sales force thoroughly understands the product. GSD files should be included in your package, or preferably made available over the internet.

PROFIBUS, the world’s most widely used fieldbus, was introduced in 1989 and is standardized under IEC61158. It is supported by more than 1400 equipment vendors around the world. The single standardized approach means users have a wide choice of vendors and products, factors that encourage higher performance and lower costs. A fieldbus-enabled plant also delivers more and better data to supervisory systems, to support improved management strategies across the enterprise.

PROFIBUS, the world’s most widely used fieldbus, was introduced in 1989 and is standardized under IEC61158. It is supported by more than 1400 equipment vendors around the world. The single standardized approach means users have a wide choice of vendors and products, factors that encourage higher performance and lower costs. A fieldbus-enabled plant also delivers more and better data to supervisory systems, to support improved management strategies across the enterprise.

Company: Phoenix Contact; Product: FL NP PND-4TX IB(-LK)

Company: Phoenix Contact; Product: FL NP PND-4TX IB(-LK)

Company: Beckhoff: Product: EK9300

Company: Beckhoff: Product: EK9300

Company: Siemens; Product: IWLAN/PB Link PN10

Company: Siemens; Product: IWLAN/PB Link PN10