Two weeks ago, in collaboration with the PROFI Interface Center (PIC), we hosted a PROFINET Network Commissioning Webinar. In the webinar, we covered a guide and useful tips for the commissioning stages. If you would like to watch the full webinar, the recording is available online.

We also had a live Q&A section during the event. The article below resolves the questions we received during the session:

Questions on PROFINET Network Commissioning

What is a PROFINET switch?

A PROFINET switch is an Industrial Ethernet switch that acts as a PROFINET device. Generally, in a PROFINET network, you can employ unmanaged or managed switches. The only requirement from a PROFINET perspective is that the switches are 100 Mbps, full duplex. Many users choose managed switches because of the additional features they provide, which can include a web interface, diagnostic information, or mirror port capabilities. PROFINET switches are managed switches that fulfill the minimum characteristics, and also add PROFINET functionality. They have a GSD file and act as a PROFINET device in the network.

How do you choose an engineering tool for network configuration?

You choose the engineering tool when you select the controller. Each controller manufacturer offers a different interface (engineering tool) for their controllers.

Do active diagnostics tools utilize bandwidth? How much?

Yes, active diagnostics tools read information from the network and utilize bandwidth. But, the bandwidth utilization will depend on the type of diagnostic tool, its location in the network, and its polling mechanism.

Is there a maximum length for PROFINET cables?

The maximum length of a copper cable linking two PROFINET components is 100 m. The maximum length of fiber cables varies from 50 m to kilometers, depending on the type of fiber. For example, some fiber cables can reach distances of over 100 km.

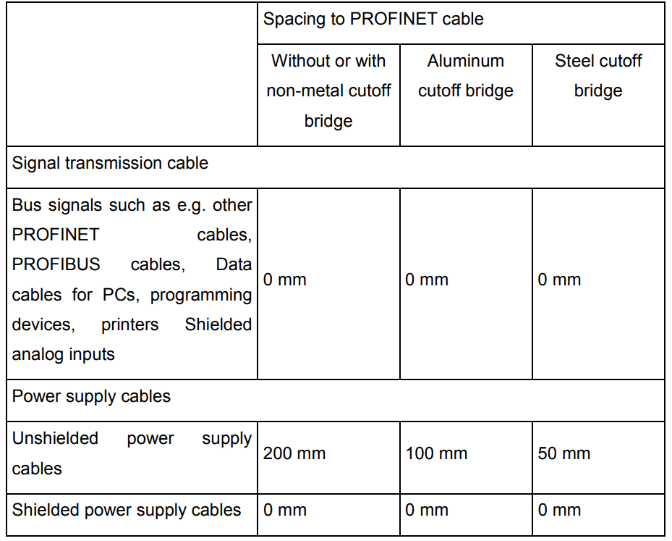

What is the cable separation between power cables and PROFINET cables?

The table below lists the recommended minimum separation distance between PROFINET cables and other electrical cables:

Where cables in different categories have to cross, they should always cross at right angles. Try to avoid running cables from various groups in parallel even for short distances. Also, remember that network components can be sources of Electro Magnetic Interference (EMI). In those cases, you can utilize shielding and spacing to protect data cables.

What is LLDP, and how does it relate to PROFINET?

LLDP is Link Layer Discovery Protocol. All PROFINET devices and controllers support it. LLDP is an IEEE standard leveraged by PROFINET that lets components share essential information (such as name and IP address) to neighboring network components. Together with PROFINET, LLDP can be used for easy topology discovery and diagnostics as well as line measurements and simple device commissioning and replacement.

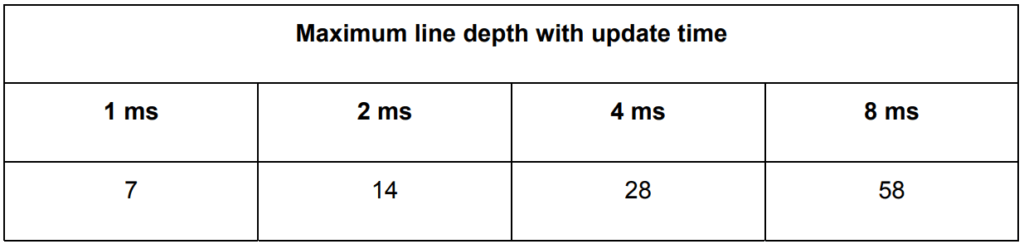

How many devices can be connected consecutively in a line topology?

From a PROFINET perspective, there are no limits in how many devices can be connected in a line topology. However, you might reach update time limitations as more devices are added to a line. The table* below compares line depth versus the expected best update time.

*The table assumes the components in the line have Store and Forward switches. Store and forward switches read and buffer the complete data packet on an incoming port. Then, the switch checks the whole frame for errors and, if error-free, sends it out the relevant port.

What makes PROFINET better than other competing protocols when it comes to commissioning?

Commissioning with PROFINET is straightforward thanks to key features to assist the user, such as topology discovery, device discovery, automatic hardware detection, simple device commissioning and replacement, and comprehensive diagnostics. Also, PROFINET offers detailed guidelines to help in all phases of your PROFINET project, including commissioning

What active monitoring tools are available?

In short, there are many active monitoring tools available in the market. For specific product information, consult with your local PROFINET vendors/distributors. Also, the PROFINET Product finder lists several tools:

Do I have to set the IP and name on an IO device?

First, you will have to configure the device. Then, write/set the device name, but typically you do not need to set the IP address, since the IO controller will set it. The only time an IP adress is needed is if there is a function on the device needed prior to the PROFINET commissioning such as the web page, PLC download in some cases, File Transfer Protocol (FTP), or other reasons.

As a device manufacturer, how do I learn more about PROFINET diagnostics and how they work?

PROFIBUS and PROFINET International (PI) offers diagnostics and topology guidelines for manufacturers. Also, you can contact a local PI Competence Center (PICC) or PI Training Center (PITC) for further information.

How do I verify a PROFINET device or controller is certified? And, are cables or passive network components certified?

PI provides a certificate to the device/controller vendor upon successful certification. The certification lists the certification date and the PROFINET version the device was certified against.

Cables, connectors and passive network components are certified by the manufacturer and must meet PROFINET and Industrial Ethernet standards to be accepted. If a network component supports PROFINET, then it also needs to be certified by PI.

Relevant Resources

Training

The PROFINET Certified Network Engineer and Installer Courses cover topics on completing a PROFINET project. These certification classes are intense, hands-on courses that will show you where and how to find and use technology-related information. During the certification process, you will learn how the underlying technology works from the application to the frame level.

Documentation

For more information on PROFINET Commissioning, you can download the guideline below:

PROFINET Guideline for Commissioning

Also, the full webinar recording and slides are available here: A Guide to PROFINET Network Commissioning