PROFINET cable manufacturers offer a range of cable types and classes for different applications, including those with special properties. These cables come in two flavors: copper and fiber optics. This post covers installation considerations for fiber optics cables.

Because fiber optic cables do not carry electrical currents or voltages they are totally immune to electromagnetic interference. Therefore the routing of fiber optic cables is less critical than for copper cables. However, mechanical protection must be provided for fiber optic cables.

Laying fiber optic PROFINET cables

Similar to copper, laying fiber optic cables requires careful attention. The following list has some key recommendations.

- Tensile Strength: If pulling the cable past the tensile strength it can be damaged. This can also occur if there is stress on an installed cable.

- Bending Radius: Sharp bends break cables over time and cause reflections.

- Avoiding Sharp Edges: Sharp edges damage/break cables over time.

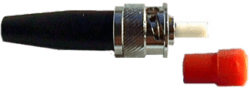

- Contamination: Fiber connectors are sensitive to contamination.

- Attach the provided dust protection caps to protect unused connectors and jacks.

- Clean the end face of the connector prior to connecting it to a device. Use a lint-free tissue soaked with isopropyl alcohol for cleaning. Then, inspect the end face with a microscope to ensure the cleaning was effective.

- Attach the provided dust protection caps to protect unused connectors and jacks.

- EMI: Fiber is immune to EMI you can lay them near other electrical cables without concern.

Advantages

Fiber optic cabling has the following advantages over copper cabling:

a) Total immunity to interference pickup. Thus fiber optic cables can be run alongside to power cables without problems.

b) Electrical isolation between the two ends. Consequently, there is no need for equipotential bonding between the two ends of the cable.

c) Longer distances are possible with glass fiber cables compared with copper

For More Information on PROFINET Installation watch this webinar: