A PROFINET network is built on standard IEEE 802.3 Ethernet. Due to challenging environments on the factory floor, most users opt for rugged industrial Ethernet cables when building an industrial network. Even though wireless access points are becoming more popular, most of today’s network connections are wired and require cabling.

Depending on the application, industrial cables must have certain capabilities. PROFINET cable manufacturers offer a range of cable types for different applications, including special properties. These cables come in two flavors: copper and fiber optics. As a reference for PROFIBUS users, PROFIBUS physical layer (RS-485) also offers flexibility with twisted-pair wiring and fiber optics.

PROFINET Copper Cables

A typical PROFINET copper cable is a 4-core, shielded copper cable (star quad). 8-core cables have been specified for high transmission rates (1000 Mbit/s). The different classes of cables vary in the structure of the wires (solid core / stranded for fixed / flexible applications and/or the jacket material and construction). PROFINET uses some Ethernet features to ensure device interoperability. The table below lists the minimum requirements for a wired copper physical layer, although a PROFINET node may implement additional protocols which may require additional features.

| Physical Layer feature | IEEE Standard |

| MAC Address | 802-2001 |

| 100Base TX Full Duplex Transmission | 802.3-2008 (Clause 24,25) |

| MAC Bridging and Switching functions | 802.1D-2004 |

| Support VLAN Priority tags | 802.1Q-2011 |

| LLDP Neighborhood Detection | 802.1AB-2005 |

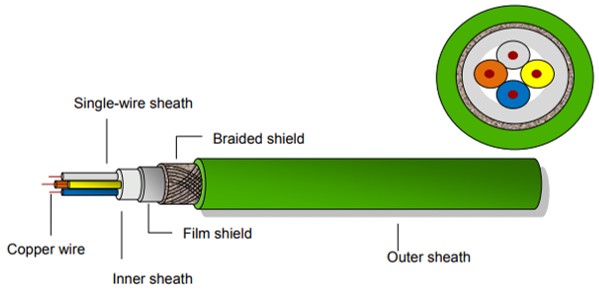

The cores of the cable are always color-coded. In a 4-core cable, wire-pair-1 is yellow and orange and wire-pair-2 is white and blue. The figure below shows a typical 4-wire PROFINET cable schema, with the cores in each wire pair arranged diametrically opposite within the cable. 8-core PROFINET copper cables consist of 4 wire-pairs, with green, blue, orange and brown wires plus a corresponding white wire for each. As in standard Ethernet applications, the maximum distance between two endpoints of communication is 100 m when using copper cabling.

PROFINET Copper Cable types

There are three main PROFINET copper cables types, mainly differentiated by the relevant applications:

Type A: Cables designed for fixed installations, they should not undergo motion after installation.

Type B: Cables designed for flexible installations. This cable type allows for occasional motion or vibrations.

Type C: Cables designed for special applications. Type C cables can withstand movement and dynamic environments, i.e trailing chains or rotary machines.

In addition, a number of special cable classes are available for PROFINET. The most common special cables are listed below with their respective applications:

- PE cables: Constant humidity areas

- Buried cables: Underground communication

- Flame retardant non-corrosive cables: Suitable for installation in areas with special fire protection regulations, e.g. halls with public access

- Trailing cable: Moving machine parts

- Festoon cable: Cranes and festoon cable systems

- Ship wiring cable: Onboard ships and offshore units

The next post covers PROFINET Fiber Optics cables, continue reading HERE

Read the full white paper: PROFINET Cabling: Overview and Implementation Considerations

PROFINET Cabling: Overview and Implementation Considerations

-Nelly Ayllon