Here are a couple news items from PI at Hanover Fair.

PROFINET in Process

PROFIBUS PA and PROFINET play well together, we are reminded. Our addition of functions such as CiR (Configuration in Run), Redundancy, Time synchronization, and Time stamping (Sequence of Events) and the proven standardized proxy solution for integrating fieldbus systems of any type, are an excellent basis for establishing PROFINET as the backbone of process automation. These four functions are a subset of the 170 requirements identified to implement process applications with PROFINET. They have all been accounted for. While PROFIBUS PA (proxied in to PROFINET) will continue to be required in hazardous areas for the foreseeable future, we’ve looked forward to PROFINET being used in instruments that are installed in normal atmospheres. At the show, process devices with PROFINET are on display. I hope to have some photos before the show ends.

The Numbers

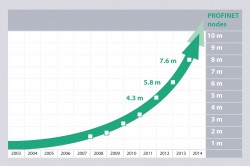

I almost hate to brag about the number of nodes of PROFINET and PROFIBUS installed… almost. The numbers actually represent  significant achievement. The numbers (nodes installed through 2013):

significant achievement. The numbers (nodes installed through 2013):

PROFIBUS: 47,400,000

PROFINET: 7,600,000

The PROFIBUS number represents an increase of 3,600,000 just in 2013. The PROFINET number includes the 20% increase in the 2013 numbers over 2012. PI uses an independent auditor to certify the numbers so an accurate count is assured. Independent market research indicates that PROFINET is the most-installed of the Industrial Ethernets and the fastest growing.

Another numbers success story is PROFIsafe with over 2,950,000 nodes installed. Because PROFIsafe can seamlessly carry safety telegrams from PROFIBUS to PROFINET, PROFIsafe-enabled PROFIBUS installed nodes can be incorporated into system upgrades that use PROFINET.

–Carl Henning