PROFINET is the leading and most advanced communication protocol for automation. Currently, in 2020, there are over 32 million PROFINET nodes installed. This article contains 10 reasons or highlights to choose PROFINET for your product or automation project.

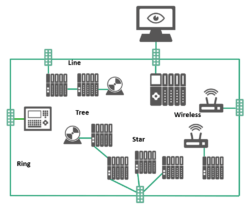

1.- Flexible Topology and Media

With PROFINET, you can implement various topology options such as line, star, tree, and even ring.

In terms of media, there are two wired media options: copper and fiber optics. Copper cables are the most common, but fiber optics applications are becoming more popular as fiber provides some key benefits. Also, wireless connections through Bluetooth and WiFi are part of the PROFINET’s specification. You can establish wireless topologies in PROFINET networks, such as Point to Point or Point to Multipoint.

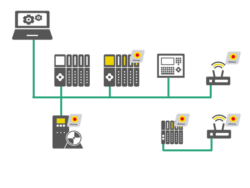

2.- User Friendly – Fast Commissioning

PROFINET offers diagnostics and topology recognition for fast and efficient network commissioning. As part of this functionality, users can accomplish the following:

- Online scan of connected devices

- Automatic assignment of IP address and device name

- Transparency in the network topology by comparing planned topology to real topology

- Comparison of module configuration (modules, serial no. , firmware, etc.)

- Simulation of network loads caused by data traffic

- Automatic device and network documentation

3.- Device Diagnostics and Asset Information

PROFINET has the best in class diagnostic mechanisms. Alarms, HMI screens, special-purpose tools, and standard IT protocols all have a place in preventing downtime and assisting with troubleshooting.

Asset Management is an additional PROFINET feature for providing information such as firmware and hardware versions, from devices outside the PROFINET address space. Asset Management is based on I&M (Identification & Maintenance) and works with standardized data sets.

4.- The Integrated Safety Solution: PROFIsafe

Functional safety (fail-safe) is the overall part of safety, which aims to prevent hazards due to the incorrect functioning of industrial machinery. Traditionally, functional safety systems relied on separately wired circuits that are expensive to build, commission, and maintain.

PROFIsafe eliminates the need for a separate safety network and reduces industrial network architectures to a single bus. PROFIsafe extends the standard PROFINET communication protocol to address unique requirements for safety-related information necessary to conform to strict safety standards. Specifically, such standards include the highest safety categories: up to SIL3 according to IEC 61508 / IEC 62061, and Category 4 according to EN 954-1, or PL “e” according to ISO 13849-1.

5.- Scalable Redundancy

Redundancy mechanisms turn a reliable system into a highly available system, adding extra components or functionality to maintain reliable operation through potential failures. PROFINET allows you to build a reliable network according to your specific requirements. PROFINET offers four redundancy options: Device Redundancy, Controller Redundancy, Network Redundancy, and Media Redundancy.

6.- Motion Control

PROFINET is the state of the art solution for motion control applications. PROFINET users can employ PROFINET IRT and PROFIdrive to install and implement drive and encoder solutions.

PROFINET IRT

Motion control applications require high performance in terms of speed and determinism. PROFINET employs PROFINET Isochronous Real-Time (IRT) for motion control applications. PROFINET IRT eliminates variable data delays in Ethernet communication by enhancing the rules used to switch Ethernet traffic and creating special rules for PROFINET traffic. It fulfills all synchronization requirements and allows deterministic communication. Specifically, PROFINET IRT enables applications having a jitter of less than 1 microsecond.

PROFIdrive Application Profile

Automation environments may require a variety of drive components for specific tasks. The tasks performed by drives and, thus, the requirements for drive technology vary considerably, depending on the industry or application. PI recognized the importance of drive devices and introduced the PROFIdrive Profile for drives, encoders, motors and their applications. PROFIdrive provides interoperability through standardized drive data sets, messages, and parameter sets as well as manufacturer-specific options to foster competition and innovation. PROFIdrive ensures vendor-neutral and interoperable drive devices by using a consistent drive interface.

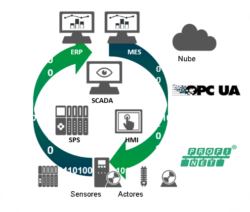

7.- IT-Integration One System for All

Because PROFINET is fully compatible with office Ethernet, it can reside (and be fully operational) on a single network cable alongside other Industrial Ethernet’s based on standard Ethernet. Also, other Ethernet protocols can coexist in a PROFINET network. For example, IT protocols such as HTTP, SNMP, LLDP are very useful for network management and troubleshooting.

8.- Good points for PROFIenergy

PROFIenergy is an optional yet beneficial feature for PROFINET components. PROFIenergy offers an entirely new way of saving energy in automation systems. With PROFIenergy, you can program an energy management strategy in the PROFINET controller. High power consumption devices can be set to go to sleep mode during breaks or downtime. With PROFIenergy, automation facilities can reduce their carbon footprint and lower energy expenses.

9.- IO-Link

IO-Link is a standardized and uniform interface for sensors and actuators. This technology enables the cyclic exchange of digital input and output process data and the acyclic exchange of parameter and diagnosis data between a Master and its associated Devices. A Master can be coupled via a gateway to an upper-level system such as a fieldbus with a PLC. IO-Link is the perfect complement for PROFINET networks. PROFINET proxies to IO-Link allow for a seamless implementation of IO-Link.

10.- Huge Organization and Support

PROFIBUS and PROFINET International (PI) was founded in 1989 and is currently the largest and most complete Fieldbus organization. The PI organization offers worldwide support. As part of the PI community, users, developers, integrators, and distributors have the support of regional associations, training centers, competence centers, and test laboratories. Also, the organization continues to improve and update its current technology portfolio to meet industry demands.

Final Thoughts

The list above is not complete. There are many more PROFINET highlights, but we can not cover them all. You can find detail descriptions of the PROFINET protocol and its applications in these two resources:

https://us.profinet.com/documentation/system-description-profinet-technology-and-application/

-Nelly