PROFIBUS PA is for process and PROFINET is for factory automation. That was true once. But not now. PROFINET is now often used in process plants as the main network backbone. And PROFIBUS PA is still used where no Industrial Ethernet can go – into hazardous areas. Hazardous areas have atmospheres that go boom when a spark occurs. So devices and connections to them must have their energy limited below the level that can cause a spark. Or they can be located in explosion-proof enclosures. These enclosures are buttoned up so tight a spark cannot escape. I worked on one explosion-proof plastics extruder project early in my career. The enclosures looked like this.

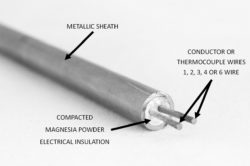

Power “cables” were mineral insulated.

My second explosion-proof plastics extruder was much easier – they put the extruder in a separate positive-pressure room and extruded through the wall.

Back from the digression: Ethernet is not approved for hazardous environments, so PROFIBUS PA will be around for a while yet – integrated into PROFINET via proxy.

But the desire is there to have Ethernet all the way to devices in hazardous environments. We are working on that. There are three main conditions to meet to have this be a success:

- Limited energy (no spark).

- Power and Ethernet over a two-wire cable.

- Copper cable lengths exceeding 100 meters.

There are still many hurdles to overcome – regulatory and standardization hurdles. But there are already several possible ways forward. Common use is still some years off in my estimation though.

PROFINEWS 142 has some further information and helpful images.

–Carl Henning