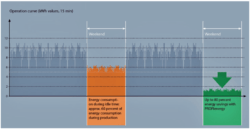

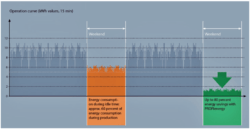

PROFIenergy energy saving potential during production pauses

PROFIenergy offers a completely new way of saving energy in automation systems. With PROFIenergy, automation controllers on a PROFINET network determine when end devices are switched into ‘sleep’ or OFF modes to save on energy usage during:

- Expected short breaks – e.g. lunchtime and shift changes

- Planned longer breaks – e.g. nights and weekends

- Unplanned pauses – e.g. breakdowns, maintenance, and upgrades

READ MORE...

By defining a standardized open profile, PI has made it possible for vendors and users to collaborate on intelligent energy management strategies using PROFIenergy.

User Benefits

- Energy and cost savings

- Fulfill laws/regulations for environmental protection

OEM Benefits

- Easy to program – using loadable function blocks

- Competitive Advantage

Device Maker Benefits

- Unique selling proposition and competitive advantage

- Builds on existing PROFINET protocol

PROFINET transmits standardized PROFIenergy commands to end devices and receives back status information and energy consumption data. PROFIenergy data uses the acyclic slots of the PROFINET communications protocol and it does not interfere with normal PROFINET processes. PROFIenergy can, therefore, be fully integrated into existing automation architectures.

PROFIenergy can be used to balance energy demand and match peak load conditions to avoid costly penalties.

For more information, read this white paper on PROFIenergy:

The PROFIenergy Profile