“I have OPC so I don’t need PROFINET.”

“I have PROFINET so I don’t need OPC.”

Neither of these statements is right. PROFINET and OPC are complementary.

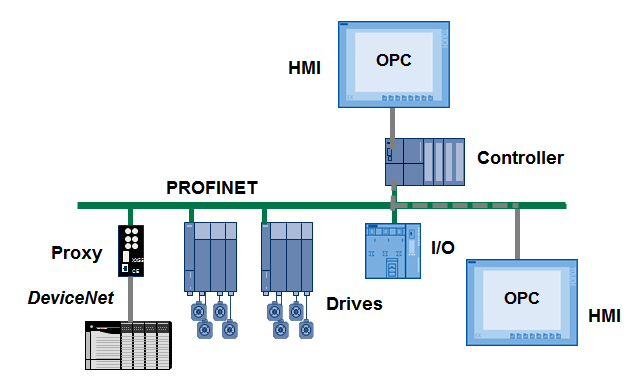

PROFINET is seen from a controller down to IO; OPC is seen from a controller up to an HMI.

PROFINET moves data fast; OPC moves information more slowly.

PROFINET is deterministic; OPC is not.

You may wonder whether I’m talking about OPC DA or OPC UA. DA stands for Data Acquisition; UA for Unified Architecture. DA is sometimes referred to as OPC Classic and it’s been around for a long time. UA is relatively new and brings together in a single architecture what used to be multiple specifications in DA days, combining DA, HDA – Historical Data Access – and others into a single, unified architecture. Hence the name. So which am I talking about? Both. The distinction is not relevant in this case. Both move information from controller to HMI.

A computer-based HMI could connect to a dedicated port on the PLC as illustrated by the HMI on the top of the controller in the illustration. Since PROFINET runs on Ethernet, and if the controller can communicate using OPC over Ethernet, then OPC and PROFINET can share the cable. The beauty of the Ethernet model is that multiple applications can run at the same time over the same cable as illustrated by the HMI lower down in the illustration. You can send and receive email while using your browser to surf the web to provide an office example of multiple applications running simultaneously.

PROFINET and OPC: different purposes, different specifications, different requirements, but work well together!

–Carl Henning

Important note: I’ve oversimplified OPC’s features to make my point of the complementary nature of PROFINET and OPC. But to do justice to OPC, I need to expand on some of these topics (especially the speed thing). Come back tomorrow for the clarification.