In the PROFINET world, PROFINET Real Time (RT) and PROFINET Isochronous Real Time (IRT) are common terms.

PROFINET RT and IRT can be employed to deliver data within a PROFINET network. PROFINET RT is equipped in all PROFINET components and fulfills the majority of industrial automation timing requirements. PROFINET IRT is optional as it is only required in high-performance applications.

This article expands on the differences and similarities between PROFINET RT and IRT communication channels, including technical details.

The Difference Between PROFINET RT and PROFINET IRT

PROFINET is a communication protocol to exchange data between controllers and devices. PROFINET can operate in demanding industrial environments and can deliver the speed and precision required by manufacturing plants. To ensure appropriate performance, PROFINET delivers data through the following communication channels:

1. TCP/IP (or UDP/IP)

2. PROFINET Real-Time (RT)

3. PROFINET Isochronous Real-Time (IRT)

4. Time Sensitive Networking (TSN)

PROFINET employs TCP/IP (or UDP/IP) communications for specific non-time-critical tasks, such as configuration, parameterization, and diagnostics.

PROFINET RT handles time-critical data exchange. An arriving PROFINET RT Ethernet frame has the PROFINET EtherType: 0×8892. Upon arrival at the destination node, the frame is directed straight from Ethernet (Layer 2) to the PROFINET application (Layer 7). The frame skips the TCP/IP layers and avoids the variable time it takes to be processed. Thus, communication speed and determinism improve significantly.

PROFINET RT meets the vast majority of the industry’s timing requirements, and almost all PROFINET frames are sent via this method. The overall performance will depend on network design, but generally, cycle times of 512 ms down to 250 µs can be achieved.

PROFINET IRT is a step beyond PROFINET RT.

Unavoidably, under high network traffic, some time-critical messages can gain jitter. PROFINET IRT eliminates variable data delays by enhancing the rules employed to switch Ethernet traffic and creating special rules for PROFINET traffic. It fulfills all synchronization requirements and allows deterministic communication with cycle times down to 31.25 µs and one µs of jitter.

PROFINET RT meets the majority of industrial automation timing requirements. Most PROFINET networks can solely rely on PROFINET RT for all cyclic data exchange. PROFINET IRT is optional and only required in specific high-performance applications.

PROFINET IRT is often used in the following applications:

- Packing machines

- Printing presses

- Plastics injection molding machines

- Wood-processing machines

- Glass-processing machines

- Ceramic-processing machines

- Mechanisms and Performance

Implementation of PROFINET RT vs. IRT

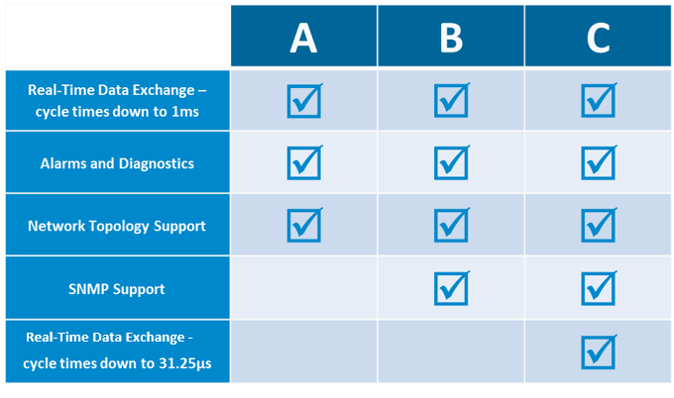

Product availability: All PROFINET products can employ PROFINET RT, but PROFINET IRT is an optional feature. Since PROFINET IRT is only needed in high-performance applications, not all products support it. Conformance Class C products support IRT.

Cables and connectors: There is no need for specialized cables or connectors in a PROFINET network. Even when employing IRT, the communication medium is standard unmodified Ethernet. As a result, users can utilize standard Ethernet cables and connectors. Copper and fiber optic Ethernet cables are suitable media options.

Wired and wireless communication: PROFINET RT can be transmitted wirelessly via Bluetooth or Wi-Fi. Due to the variable time it takes to convert wired signals to wireless communication and vice versa, wireless communication is not suitable for PROFINET IRT.

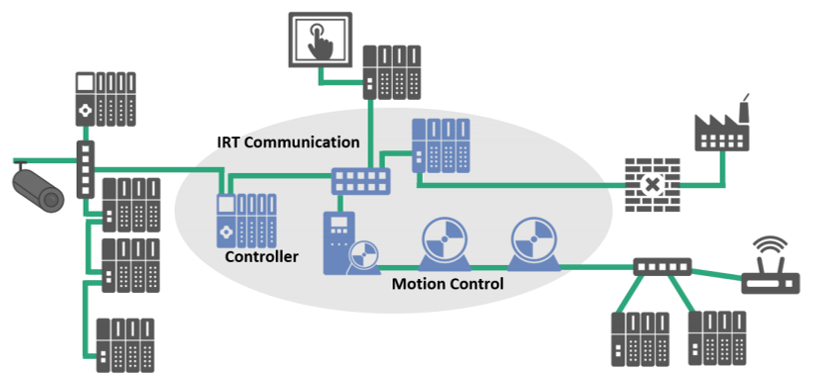

Topologies: There are no topology restrictions when employing PROFINET RT or IRT. The user can implement line, star, tree, or ring configurations. The only requirement is that all nodes utilizing IRT have to be interconnected on the same domain or network section (like the example below). Other PROFINET or Ethernet nodes can be connected but must not interrupt direct connection between IRT devices.

Standalone switches: All switches in the IRT domain must support IRT. The diagram below illustrates the concept. Utilizing standalone switches can be avoided by using integrated switches in devices with multiple ports.

Outside IRT domains, no specialized switches are required. Still, industrially graded switches are recommended.

Learn more about PROFINET RT and IRT with this short and informative white paper: