Manufacturing environments, where PROFINET is most commonly used, are characterized by having challenging environmental conditions. In that environment, standard Ethernet cables, like those you find in your office or home, might break or damage easily. Extreme temperatures, moisture, vibrations, electro magnetic interference, and many other factors contribute to the deterioration of cables.

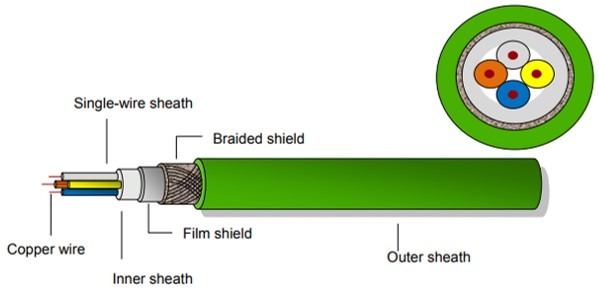

Due to the challenging environment meant, industrial Ethernet cables are a common choice in automation facilities. On the wire, Industrial Ethernet is just Ethernet. Yet, Industrial Ethernet is characterized by rugged hardware, and its wiring is protected with shielding and jacketing.

Many vendors offer Industrial Ethernet solutions, and some produce cables specifically for PROFINET, which are called PROFINET cables. PROFINET cables are a subset of Industrial Ethernet cables. They often come with a green jacketing and comply with ruggedized specifications that have been standardized by PROFIBUS and PROFINET International (PI).

The diagram below shows a typical 4-wire PROFINET cable schema, with the cores in each wire pair arranged diametrically opposite within the cable.

PROFINET cable manufacturers offer various cable types and classes for different applications, including those with unique properties. These cables come in two flavors: copper and fiber optics.

Can you employ standard Ethernet cables for PROFINET?

You can employ standard Ethernet cables to build a PROFINET network. However, the Ethernet cables you might encounter in a home or office environment might not be the best choice.

Standard Ethernet cables can be weak and might lack shielding. Such cables will likely not last very long on the factory floor. For that reason, the vast majority of PROFINET installations use industrial Ethetner cabless.

Learn more about cables in PROFINET projects with this short and informative white paper: