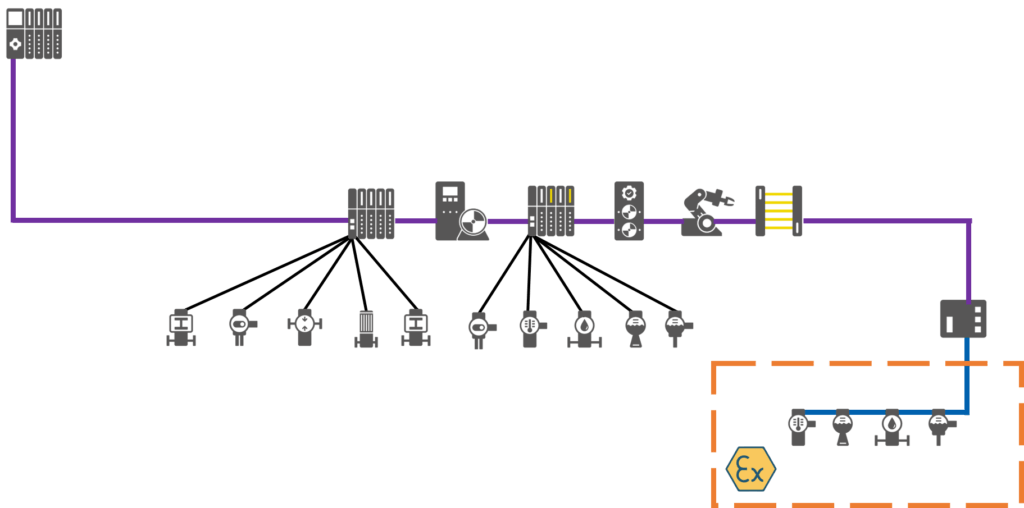

PROFIBUS devices are divided into three classes based on their functions:

PROFIBUS devices are divided into three classes based on their functions:

- PROFIBUS DP master (class 1)

- PROFIBUS DP master (class 2)

- PROFIBUS device

PROFIBUS DP master (class 1): A PROFIBUS DP master of class 1 (DPM1) is a master who uses cyclical communication to exchange process data with its associated devices. Devices of this type are often integrated into a memory programmable controller or an automation station of the process control system.

PROFIBUS DP master (class 2): A PROFIBUS DP master of class (DPM2) was originally defined as a master used as a tool in the context of PROFIBUS system commissioning. In the course of the DP-V1 and DP-V2 functional expansions, a DPM2 has been more specifically defined as a master which can be used to set device parameters via acyclical communication. Devices of this type are usually part of an engineering station used for device configuration. A DPM2 need not be permanently connected to the bus system.

PROFIBUS device: A PROFIBUS device is a passive communication node that reacts to prompts from the master by sending a response message. Devices in this class are usually field devices (remote I/O, drive, valve, transducer, analyzer) that acquire process variables or play a part in the process utilizing manipulated variables. A differentiation is made between compact and modular devices. A modular device comprises a head station containing the fieldbus interface and several slots into which various modules can be inserted. By combining different modules, modular devices can be adapted flexibly to respond to prevailing input and output data requirements. Compact devices have a fixed set of input and output data – comparable to a modular device with precisely one permanently installed module.

The majority of devices in process automation are modular devices on which, rather than being physically present, the individual modules exist in the device software (virtual modules). These virtual modules are activated or deactivated when cyclic communication is established. The virtual modules, of which a device in process automation can make use, are specified in the profile for PA devices.

Frequently, PROFIBUS master devices support the functions of both a DPM1 and a DPM2. Similarly, there are also automation devices that can operate as both masters and devices. In practice, it is rarely possible to unequivocally categorize physical devices into the function classes outlined above.

For a complete introduction to PROFIBUS, consider taking this free course: us.profinet.com/profibusonline. Our course includes technical details of the technology and a complete overview of network design, configuration, installation, commissioning, and maintenance for PROFIBUS DP and PROFIBUS PA.

For a complete introduction to PROFIBUS, consider taking this free course: us.profinet.com/profibusonline. Our course includes technical details of the technology and a complete overview of network design, configuration, installation, commissioning, and maintenance for PROFIBUS DP and PROFIBUS PA.

- Students receive a certificate for 5 Professional Development Hours (PDH) after completing the course

- The entire course is available online at no-cost

- Challenging quizzes help students test their understanding of the material

- The course includes educational content for end-users, OEMs, system integrators, manufacturers of automation devices, distributors, and students.