The process industries have many challenging production requirements. For example, in some applications, systems must run continuously without interruptions; not even emergency stops are possible. For those scenarios, PROFIBUS and PROFINET International (PI) specified a PROFINET feature to ensure continuous processes. Such feature is Dynamic Reconfiguration (DR). DR allows users to reconfigure, insert, remove, or replace devices or modules without stopping the control application. There is no need to shut down or interrupt the network for plant repairs, modifications, or expansions.

DR is not mandatory in all PROFINET products; it is an optional feature. To use the DR feature, the Engineering tool, the Controller, and any devices involved must support DR. But, mixed networks with DR and non-DR supporting devices are possible.

Dynamic Reconfiguration Explained

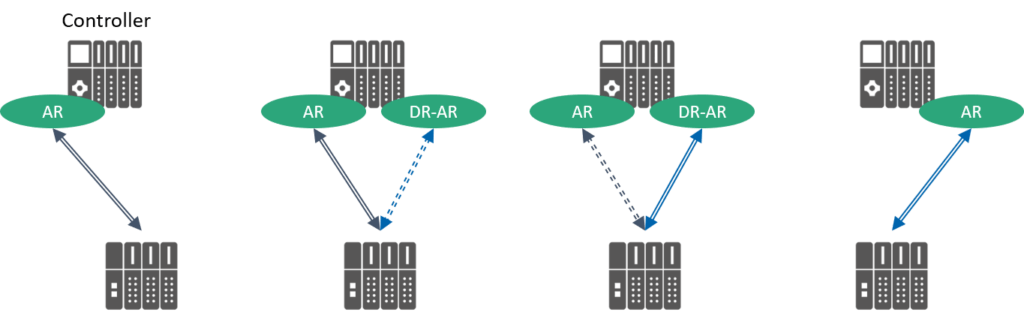

Without DR, the user must restart the Controller and stop production when making changes to an Application Relation (AR). With DR, the switchover is seamless, no restart is required. The diagram below illustrates how DR works when updating the AR between a controller and a device.

- The controller and the device are running under a specific AR.

- The user defines a new configuration, and the Engineering tool establishes a second AR (DR-AR) with the new configuration. But, the original AR still controls the IO.

- Then, the Engineering tool initiates the switchover. The second AR (DR-AR) becomes the new controlling AR.

- Finally, the old AR is removed, and the new AR is relabeled from DR-AR to AR.

If you would like to learn more about DR or PROFINET in Process Automation, click on the link below and watch a free webinar: