Every industrial network has a unique set of requirements as it must fulfill a variety of different tasks. Some tasks require high-speed synchronized communication. Others are not as time-critical.

PROFINET is the world’s most advanced Industrial Ethernet solution. It is a communication protocol to exchange data between controllers and devices. PROFINET can operate in challenging industrial environments and is capable of delivering the speed and precision required by manufacturing plants. To deliver messages with the appropriate speed and determinism, PROFINET employs three communication channels for data exchange: TCP/IP and UDP/IP, Real-Time (RT), and Isochronous Real-Time (IRT). This post explores the PROFINET RT channel. First, we will start with a quick introduction to explain the motivation behind PROFINET RT. Then, we will proceed to resolve the most common questions about PROFINET RT.

Ethernet-Based Networks

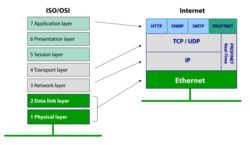

Ethernet-based communications can be represented by a seven-layer model: the ISO/OSI Reference Model. The model generically describes the means and methods used to transmit data. Each layer has a specific name and function, as shown in the figure below. The layers from the bottom to the top are Physical, Data Link, Network, Transport, Session, Presentation, and Application. PROFINET lives in Layer 7; it is an application.

TCP/IP and UDP/IP

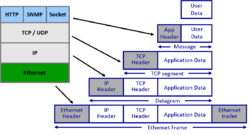

The first PROFINET communication channel is TCP/IP and UDP/IP. PROFINET can only use TCP/IP (or UDP/IP) communications for non-time-critical tasks, such as configuration and parameterization. When sending data via TCP/IP, additional information is added to the data packet. The additional information, as shown in the figure below, can make Ethernet frames relatively large. When sending such Ethernet frames, the sender ‘packs’ the data and the receiver ‘unpacks’ it, in a process commonly called encapsulation. Encapsulation can add significant jitter and latency. As a result, the TCP/IP communication channel is unsuitable for time-critical tasks. Then, PROFINET needs to employ another mechanism for real-time data exchange. Thus, PROFINET employs the PROFINET RT communication channel for time-critical data exchange.

The following video summarizes TCP/IP communication in PROFINET networks:

PROFINET Real-Time

PROFINET RT handles time-critical data exchange. An arriving PROFINET RT Ethernet frame has the PROFINET EtherType*: 0×8892. Upon arrival at the destination node, the frame is directed to the PROFINET application immediately. The frame goes directly from Ethernet (Layer 2) to PROFINET (Layer 7). It skips the TCP/IP layers and avoids the variable time it takes to be processed. Thus, communication speed and determinism improve significantly. PROFINET RT meets more than 95% of industrial automation timing requirements, and almost all PROFINET frames are sent via this method.

PROFINET Real-Time Frequently Asked Questions

What cycle time can I expect with PROFINET RT?

A device cycle time can be specified individually for connections in the controller’s engineering tool. The controller has a set number of cycle times available, which vary within the range of 250 µs to 512 ms for PROFINET RT. The cycle times available will not only depend on the controller but also the network. Following proper design guidelines can decrease network load and improve update times.

Do I need special networking components for PROFINET RT?

No, there is no need for specialized networking components. PROFINET is based on standard Ethernet. Therefore, you can utilize standard Ethernet components. For example, you can employ a commercial off the shelf unmanaged Ethernet switch. The only requirement for switches in a PROFINET network is 100 Mbit/s full-duplex (and most switches in the market fulfill this requirement).

What PROFINET devices support PROFINET RT?

All PROFINET components support PROFINET RT. There is no need to search for a specific feature in a product; all PROFINET devices support it.

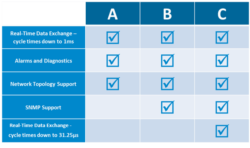

PROFINET products have a defined set of features that are mandatory based on its conformance class. There are three PROFINET conformance classes: A, B, and C. Conformance Class A (CC-A) is the most basic, while C (CC-C) is the most advanced. The Conformance Classes build upon each other; for example, CC-C contains all functions from CC-A and CC-B. As shown in the table below, all conformance classes support alarms and diagnostics, network topology support, and real-time data exchange (PROFINET RT).

Can I achieve shorter cycle times with PROFINET (beyond PROFINET RT)?

Yes, for the most demanding applications, PROFINET can use additional techniques for even faster performance with the PROFINET IRT channel. PROFINET IRT is a step beyond PROFINET RT.

Unavoidably, under high network traffic, some time-critical messages can gain jitter. IRT eliminates those delays by enhancing the rules employed to switch Ethernet traffic, and by creating special rules for this PROFINET traffic. You can learn the details about the PROFINET IRT communication channel in this article: PROFINET Isochronous Real-Time Communication.

*The EtherType is a standard field present in Ethernet packets. It is a 2-byte piece of information that describes which type of protocol you are using. The 0x0800 EtherType is a common one. It is utilized for IP based protocols.

For more information on the PROFINET communication channels and additional PROFINET functionality, download the document below:

https://us.profinet.com/documentation/system-description-profinet-technology-and-application/

-Nelly Ayllon