One hundred attendees of the ARC Forum in Orlando stayed for the last morning’s sessions on PROFINET (despite weather-inflicted travel woes). The session expanded on ARC’s theme of the information driven enterprise by showing how PROFINET enables the information driven enterprise. Three PI North America Board members described their focus on PROFINET. They were introduced by Michael Bryant, executive director of PI North America who hosted the two sessions.

Raj Batra, president of the Industry Automation Division at Siemens Industry, Inc., showed how PROFINET provides efficiency, performance, and flexibility in sustaining industrial automation products. He used an example from the automotive industry, setting the stage for the next speaker.

Mike Bastian, controls manager for Ford’s Global Powertrain group, described their reliance on PROFINET to stretch from IO to the enterprise, perfectly mirroring the session’s theme. David Greenfield, editor-in-chief of Automation World wrote extensively about Mike Bastian’s presentation in “Ford’s Focus on Control.”

Bernie Anger, General Manager at GE Intelligent Platforms, described how GE Intelligent Platforms leverages PROFINET as their Industrial Ethernet backbone. It’s an integral link between IO and the cloud.

System integrator, ICR Engineering’s David Loveridge told why the network matters; namely, that PROFINET allows the move from proprietary networks to an open, multi-vendor architecture. He then described the characteristics they used to settle on PROFINET, finding it provided better determinism, lower jitter, reliable redundancy, and available functional safety.

Michael Rothwell, Director of Control and Industry Solutions at Phoenix Contact, focused on PROFINET and the Internet of Things (IoT). He noted that the Manufacturing Renaissance in North America required data and connectivity down to the device level. And more data at the device level means efficient, reliable PROFINET-based communications will continue to be essential.

Chris Muench, the CEO of C-Labs, explained how PROFINET has been extended to and integrated with the Internet of Things. He emphasized the need for secure communications and how that empowered remote maintenance workers.

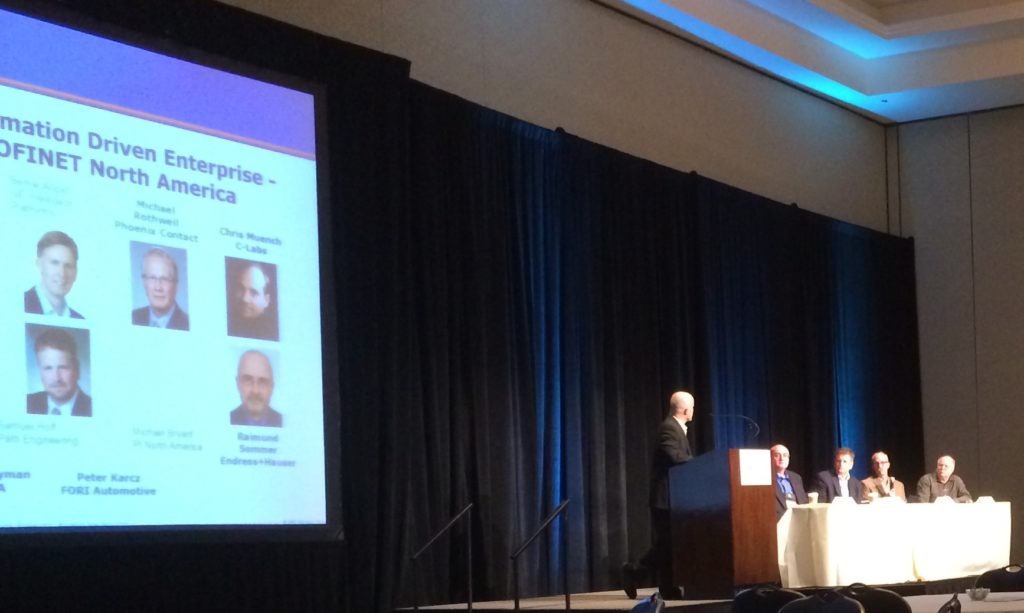

After the morning break, David Greenfield moderated a panel discussion on PROFINET. Panelists included David Loveridge of ICR Engineering, Sam Hoff of Patti Engineering, Dave Heyman of Kuka Assembly & Test, and Peter Karcz of Fori Automation. Topics included safety, security, wireless, and diagnostics. David Greenfield has reported on the latter topic in “Industrial Ethernet: Diagnostics.”

The session concluded with a presentation on process and discrete synergies by Raimund Sommer, Managing Director, Endress+Hauser Process Solutions AG. His wide-ranging presentation covered where fieldbuses are used today and what it will take for Industrial Ethernet to supplant them.

–Carl Henning