The iPar Server is not an Internet tool for scoring your golf game; it’s a parameter repository to help in device replacement.

One of the topics we don’t have time to cover in our PROFIBUS and PROFINET one-day training classes is the iPar Server. iPar is short for iParameter. It’s another example of the depth of functionality in PROFIBUS and PROFINET. The PROFINET System Description describes the iPar Server this way:

Parameters determined on a plant-specific basis are saved and loaded autonomously. The iPar server allows vendor-neutral loading (e.g., via TCI) of individually-assigned parameters optimized for the specific plant as well as automatic archiving on a parameter server. Downloading also occurs automatically during device replacement.

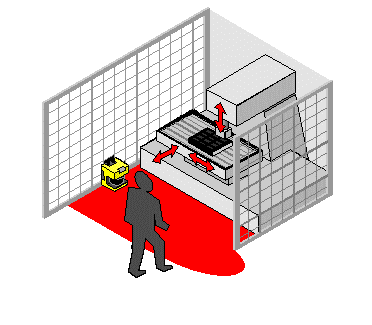

iPar Servers are often associated with PROFIsafe, the functional safety application profile that runs over both PROFIBUS and PROFINET. In that use, an iPar Server can greatly speed device replacement. Let’s say that part of the functional safety system is a laser scanner (the yellow device on the floor) with multiple patterns available (one pattern is shown in the picture below):

If the laser scanner has to be replaced, you don’t want to be required to manually reconfigure it before getting the line running again. Because the iPar server automatically saves and restores the device-specific, application-specific configuration, you don’t have to delay restarting the line to manually connect additional software tools to reconfigure it!

If the laser scanner has to be replaced, you don’t want to be required to manually reconfigure it before getting the line running again. Because the iPar server automatically saves and restores the device-specific, application-specific configuration, you don’t have to delay restarting the line to manually connect additional software tools to reconfigure it!

You can find more about the process the iPar Server uses online in the description of how to implement PROFIsafe.

Did you notice how I glossed over the acronym TCI? That’s the Tool Calling Interface and a good topic for a future post.

[Speaking of one-day training classes, our last one for 2010 is PROFINET in Detroit tomorrow. Watch for the 2011 schedule at www.us.profinet.com.]

–Carl Henning