I saw a recent magazine article outlining six steps to take to implement the Industrial Internet of Things (IIoT). It was mostly political – form a team, get buy-in from a C-level executive, etc. It’s not that I think the political approach is not valuable, but most of us live in a technical world. So here are the technical steps to the IIoT.

1. Educate yourself. What is IIoT? Relate it to automation.

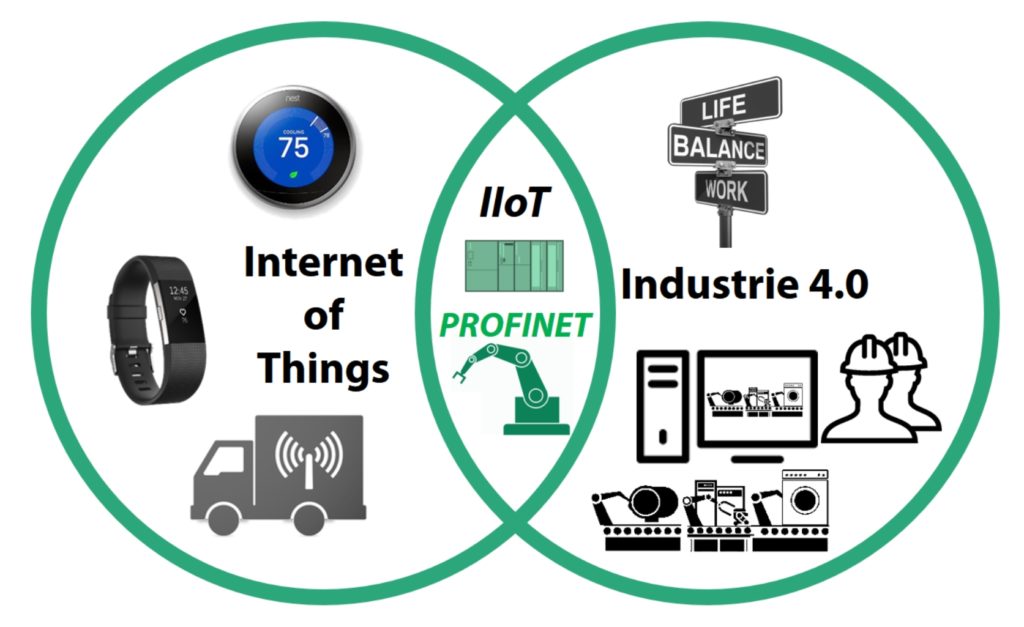

IIoT is a part of both the Internet of Things and Industrie 4.0. This diagram shows the relationship:

I define IIoT like this: IIoT involves interconnecting devices, moving their data to a database (possibly in the cloud), then analyzing that data to discover process savings or to predict and avoid downtime.

To follow my informal development of where IIoT fits follow these blog posts starting with the oldest one.

2. Assess your plant’s level of automation.

Do you have devices on older, non-Ethernet networks? Fear not, PROFINET provides proxies to integrate them into PROFINET. From there, their data can travel to the cloud and analytics where the oney-making magic of IIoT happens. You can integrate PROFIBUS, DeviceNet, Interbus, IO-Link, AS-interface, HART, Foundation Fieldbus, and many more. And in keeping with IIoT’s emphasis on open standards, proxies are defined in the open PROFINET standard.

3. Mind the gap. What is my facility lacking? Where am I short of IIoT?

You probably are missing data storage and analytics, but all the major automation suppliers can provide these as a service. This service is not trivial, but they all depend on getting the required data. That’s where we come in. If you don’t have an Industrial Ethernet, plan to add PROFINET. That’s where the needed data will come from, even data from older serial fieldbuses.

4. Plan the upgrade. (Here’s where the politics come in. Or the “show me the money” comes in.) An ROI is required.

Justify the project with whatever your local company politics require.

Then PROFINET will help you in this phase with a Design guideline, Installation guideline, Commissioning guideline, and Security guideline. We offer many avenues to educate yourself for this phase: free classes; week-long, in-depth classes; webinars; newsletter: videos; and documentation. Browse us.profinet.com for all of these.

5. Implement and commission.

The aforementioned guidelines will help. But if you need help from people, look for PROFINET Certified Network Engineers (or become one). PI is the only fieldbus/Industrial Ethernet organization that has accredited competence centers that provide assistance. There are over 50 of these around the world. If you get stuck, call them.

6. Monitor.

Commissioning is just the beginning. Your production system will be around for many years. PROFINET helps you keep the lines running. Redundant media, controllers, and devices keep any one failure from shutting you down. And PROFINET’s diagnostics are comprehensive; helping you when something breaks and helping you prevent a breakdown from occurring.

7. Bask in the glow of management’s appreciation of your accomplishment. (Hey it COULD happen, couldn’t it?)

–Carl Henning

Learn more about IoT, IIoT, and Automation with our free PROFINET classes across North America: